The Datapaq Furnace Tracker for Metals Heat Treating from Fluke Process Instruments features the Datapaq TP6 data logger, choice of thermal barrier (Datapaq TB40 or TB49), thermocouples and our intuitive Datapaq Insight™ Software to create a complete solution.

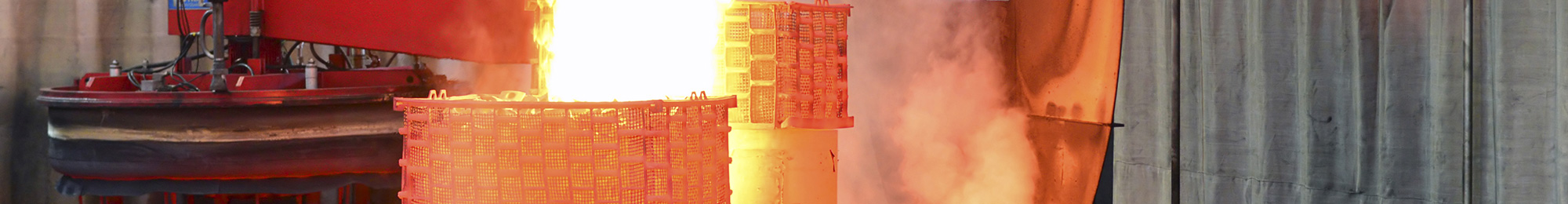

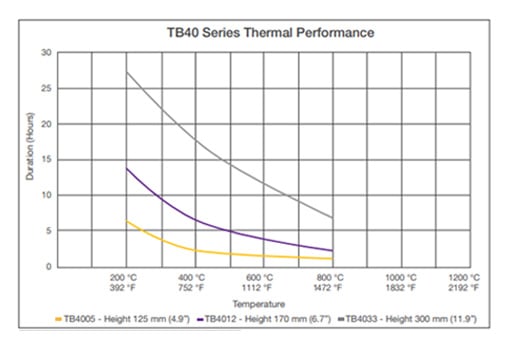

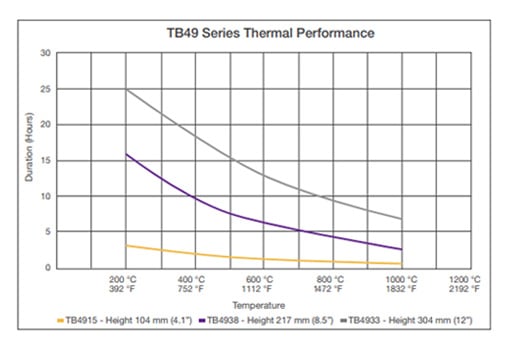

Furnace Tracker Systems that include thermal barriers from the Datapaq TB40 Series are designed for use in conveyorized or batch furnaces, operated up to 800°C (1472°F). For processes at higher temperatures, the Datapaq TB49 Series features floating plate technology and more exotic materials, which enable use up to 1050°C (1922°F).

Data Logger

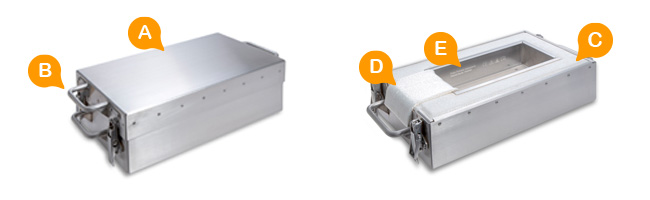

The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ Software, you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections.

- Available in 10 and 20 channel configurations and two case styles.

- Water resistant (IP67 rated).

- Communication via USB or Bluetooth

- Real time telemetry via USB, RF telemetry and Bluetooth.

- Alkaline, NiMH and Lithium battery options.

- Compatible with the Datapaq Insight™ for mobile application.

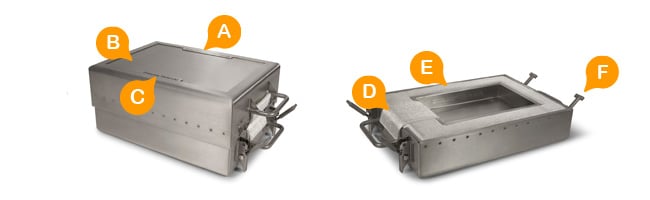

In most applications, the environmental conditions and process parameters in the furnace – such as temperature, duration and atmosphere – drive thermal barrier selection. Although different data logger configurations and software options are available, these are less critical compared to thermal barrier selection.

In most applications, the environmental conditions and process parameters in the furnace – such as temperature, duration and atmosphere – drive thermal barrier selection. Although different data logger configurations and software options are available, these are less critical compared to thermal barrier selection.