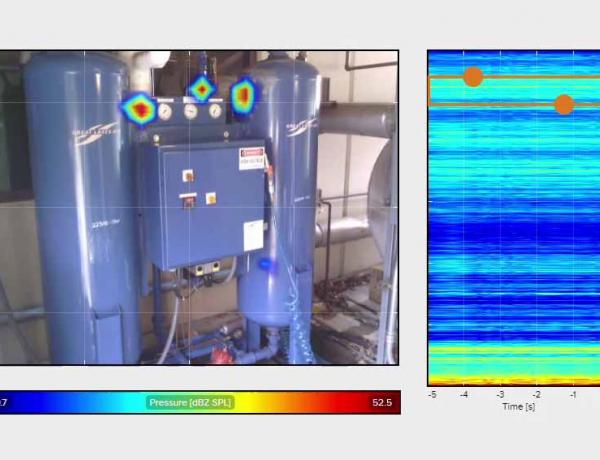

A leading chemical manufacturer faced employee safety concerns due to gas leaks from pipes and valves. They sought a solution to detect leaks of industrial gases like oxygen, nitrogen, and carbon monoxide. Their current process involved manual testing with soapy water, which was time-consuming and required employees to wear personal protective equipment (PPE) in certain areas.

After experiencing a significant safety issue in their factory, the company wanted a safer and more automated monitoring system. After two months of trials in various plant locations, they purchased three SV600 Acoustic Imagers to monitor specific areas and equipment that required 24/7 gas leak monitoring.

The SV600 improved the safety of the inspection/maintenance team and reduced inspection time for those areas that were difficult to access. They could visually show the leak's location and record videos and photos to document the inspections and provide reports. The company also benefited from earlier gas leak detection via the SV600, which reduced waste and saved money.

We provided an accessory solution for the SV600, including a carry case, wireless POE router, battery, and holder. The accessory to the SV600 solution allowed the customer to monitor multiple assets in several areas continuously.

The success of the SV600 led to global sales opportunities for 24/7 asset monitoring applications in chemical plants and other facilities where gas leak detection is a key requirement driven primarily by employee safety. Companies in various industries can benefit from similar solutions to improve safety and optimize their processes.