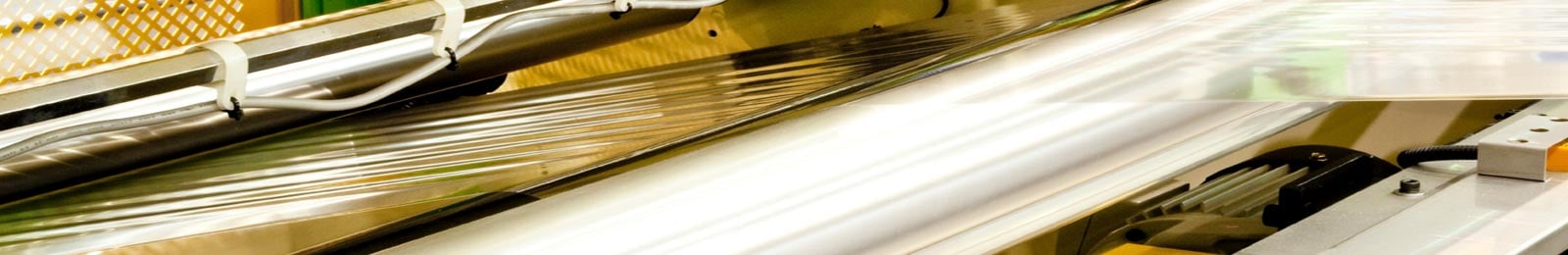

Plastic Processing

Improve productivity and efficiency of plastic processing using accurate temperature data

Gain the ability to measure temperatures of individual targets or the complete width of the target

Use noncontact infrared sensors to avoid product contamination or process interference

Quickly detect potential problems to avoid scrap, waste and energy loss

Control temperature of fast moving parts