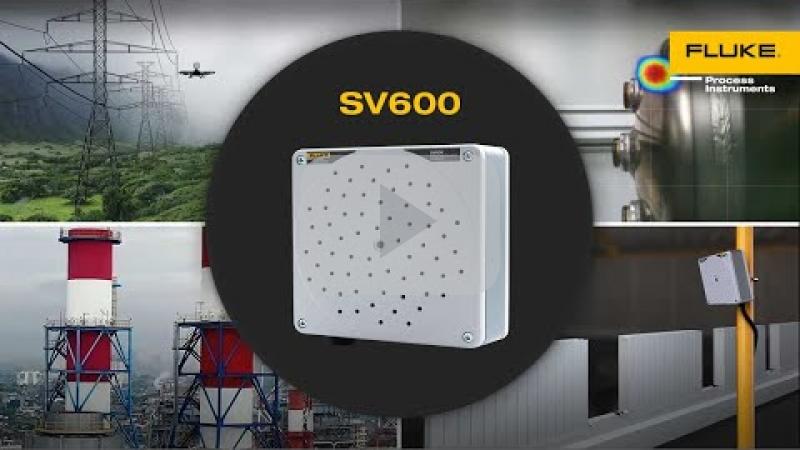

By using an array of sophisticated sound sensors, the SV600 can be mounted close to any equipment or asset, to any area of the production line, or where human access is restricted or dangerous to ensure you can monitor the most important parts of your facility without interruption.

As a fixed, automated solution, the SV600 integrates with your process and eliminates the need for lengthy fault-finding processes such as soapy water tests, when used as part of your product leak testing process. By continuously monitoring your environment, you can quickly detect and fix air leaks – reducing your consumption of compressed air and energy to help save your facility money.

Key Features:

- High-end 24/7 acoustic monitoring

- 64-Digital MEMS microphones placed in a Sunflower Array

- Integrated visual light camera

- Powerful processor for onboard real time processing

- Sound classification

- Frequency filtering

- dB values and sound intensity mapping

- Event triggering

- Ethernet network communications interface with installed 8-wire M12 fieldbus or RJ45 connector

- Power over Ethernet (POE)

- Ingress Protection IP54

- Option for IO support through fieldbus coupler