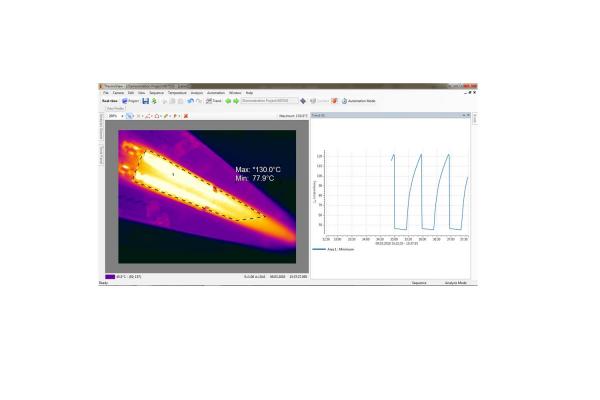

The ThermoView TV40 is a high-performance industrial fixed thermal imaging system that allows you to expand your understanding by providing continuous infrared and visual feeds to visualize temperature data. The TV40 offers a fully integrated temperature control, monitoring, and data archiving solution.

With the ability to personalize your integration, the TV40 allows you to automate your process by programing unlimited "areas of interest," programable alarms, utilize advanced pass/fail logic, and perform safety or asset inspections. Feed the data to your PLC or view feeds remotely.

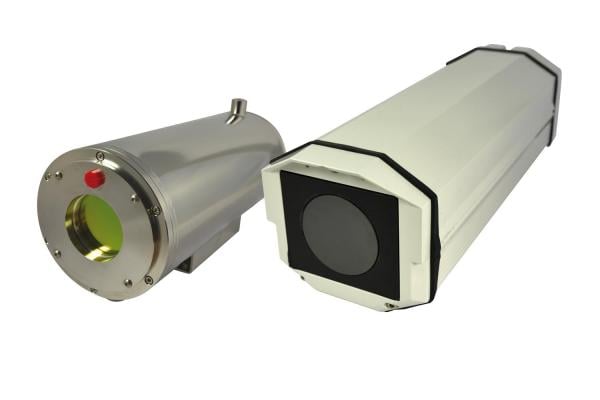

Hardware

The rugged TV40 thermal camera lets you visualize the temperature data you need anywhere in your process with reliable, high-quality 320x240 and 640x480 infrared resolution options. Several key features:

- IP67 (NEMA 4) housing that guarantees long-term thermal imaging in the harshest environments (air purge and other accessories available)

- Simultaneous infrared and visible sighting for easy alignment and the ability to quickly locate potential problems

- Multiple pre-calibrated lenses are field interchangeable with remote motorized focus, allowing you to change your thermal camera lenses on-site without the need for additional calibration

- Standard I/O modules, GigE Vision, and other direct communication protocols on infrared camera for easy integration into your existing control system

- Power Over Ethernet enables the fixed thermal camera to be supported by your existing power switch

For additional infrared camera key features, check out the ThermoView TV40 Datasheet or speak with an expert to discuss how the imager could support your application.