Why is Food Cooked?

The benefits of cooking food are well documented to include among others, improved flavor, palatability, texture, shelf life and more recently reduced preparation time in the home. Food processors worldwide increasingly focus on the supply of ready cooked products in order to add value to the product and so maximize market appeal.

In many food sectors, particularly meat and poultry the overriding benefit and critical requirement of cooking still remains product safety. The domestic consumer when purchasing pre-cooked food from the supermarket or at a restaurant expects the food to be safe to eat. With increased media interest and public awareness food poisoning outbreaks are being traced back to the offending food processor. The potential outcome in terms of product recall, loss of customer confidence for a food brand or supplier can be catastrophic.

The HACCP Principle

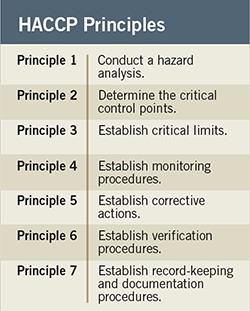

Faced with market and regulatory pressure to provide safe products, food companies worldwide are adopting HACCP. HACCP stands for Hazard Analysis and Critical Control Point, and involves the systematic assessment of all the main steps involved in a food operation and the identification of those steps, which are critical to the safety of the product. The HACCP protocol contains seven main principles, which are used to identify, control, monitor and document potential hazards in the food processing operation. For further processing operations in poultry, the most important critical control point within the HACCP protocol will be the cooking and chilling process.

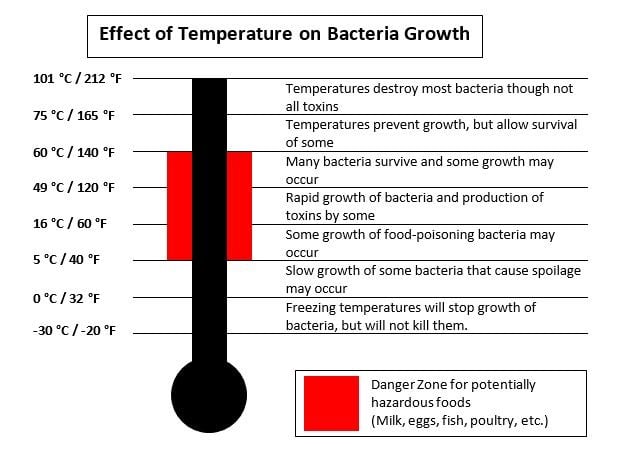

As illustrated in Figure 1, potentially lethal bacteria such as Listeria Monocytogenes have a critical interdependency on temperature. Getting the cook & chill process wrong could result in accelerated bacterial growth rather than the intended killing of bacteria.There is a fine dividing line between bacteria growth at 120 °F and bacteria kill 165 °F.

Implementing the HACCP Plan in Practice

For many food processors HACCP principles as detailed in Table 1, are commonly implemented. A critical point of the process when cooking or chilling food is the manual testing of product temperatures at the exit of the oven or chiller with a hand-held thermometer. This action in itself is easy to implement but does have some issues that must be managed with care.

- Does the exit temperature accurately reflect the peak product temperature?

- Is the operator measuring the correct part of the product? ie core or surface

- Is the operator measuring products over the entire cook / oven area - top and bottom of a static food rack or left to right on a conveyorized oven?

- Is manual recording of product temperature readings acceptable? It has the potential for error in transposing readings from a digital display to QA test sheet.

The greatest deficiency of the use of a hand-held thermometer is that it only provides a point measurement that is post process. If the product core temperature is greater than the specified safe minimum everything is fine and processing can continue with confidence. In the event of the core temperature being less than the target value we can see from Table 1 principle 5, that in the event of a product failing to meet the critical limit the system must be analyzed and a corrective action implemented. An undercooked product could result from the oven being run using incorrect recipe parameters, or the oven itself not performing correctly. What options are left to the QA manager when he faces a situation where the product core temperature is too low yet the oven controller is set correctly?

The reading from the oven controller display does not give the whole picture of what is happening in the oven. The oven temperature control sensor is often located away from the product and cannot reflect the temperature experienced by the product. The temperature experienced by the product can be affected by many variables including air velocity and moisture level, and may be independent of the oven set point. Poorly balanced air flow within an oven can result in temperature imbalance resulting in significant different cook rates dependent on position within the volume of the oven

The use of a "through process" data logger monitoring the product temperature throughout the cook and chill process can be used to rapidly find the cause of an incorrect product exit temperature thus enabling process engineers to follow principle 5 (regarding establishing corrective actions). It can also form part of the regular measuring procedure compliant with principle 4, see table 1

In addition to compliance with HACCP guidelines, a "through process" profiler will help in establishing more efficient recipes, confirm effective corrective actions and support a quality system that is preventative rather than reactive.

Conclusion

In summary the regular use of a "through process" temperature profiling system is the best method to satisfy all the principles of the HACCP protocol for conveyorised or rotary cook and chill processes.

The benefit of a “through process” system over the hand held thermometers is that it provides a complete record of the product and oven temperatures during the process. This information is required if the CCP target value is not attained as it will highlight problem areas in the cook such as cold spots which maybe causing the undercook.

Thermal profile data is also invaluable to verify that any action to correct the fault has been successful.

By adopting a "through process" approach, a clear understanding of the effect of the oven’s operating characteristics (on the product cook profile) can be established. This information helps with product development and optimizing the cook cycle to guarantee product quality and product yield without having to compromise on product safety.