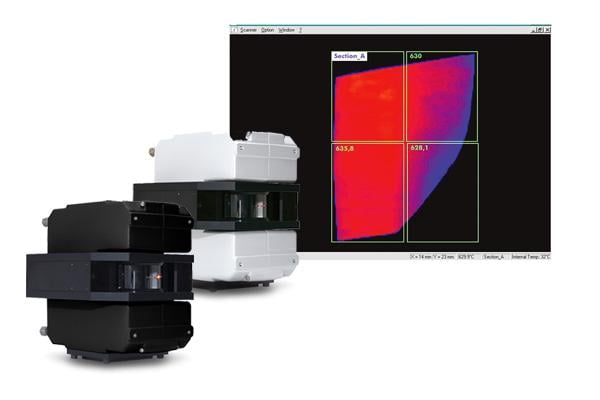

The GS Thermal Imaging System for Glass Processes from Fluke Process Instruments features a variety of linescanning systems that provide continuous, accurate and real-time thermal images and temperature measurements for moving processes and low emissivity glass products.

Each system comes in a wide choice of spectral and temperatures ranges to accommodate a variety of applications. The series also features dedicated hardware and software options, which have been created specifically for specialized glass applications – such as glass bending, forming, annealing and tempering – and industrial environments.