No additional software required

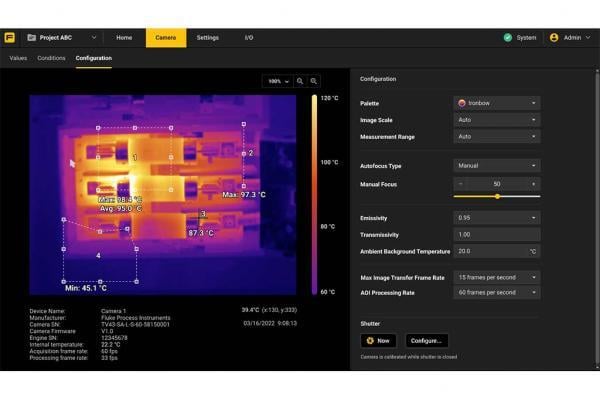

- TV30-SA: An accessible, standalone thermal imaging solution with onboard analytics and remote setup via web browser

- TV30-GE with ThermoView Software for enhanced inspection capabilities: Ideal for complex tasks

Designed for the toughest conditions

- Rugged and reliable IP67 housing is resilient and built to last

- With an air purge, water-cooling jacket, and other accessories available, you can be sure your equipment will stand up to whatever is thrown at it

Avoid costly downtime

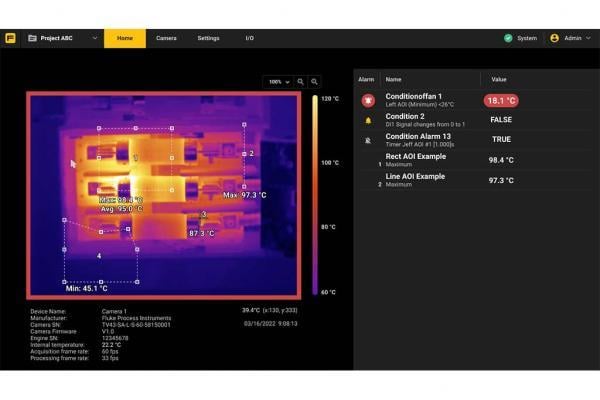

- The TV30 identifies defects and can alert you when any anomalies are detected

- Continuous 24/7 monitoring

Key Features

- Multiple fieldbus protocols for simple integration

Integrating a system is never easy. Without the right tools, it can cost you time, money and frustration. Our fieldbus protocols are designed to make integration with most PLCs simple and cost-effective. OPC UA, and MQTT are all supported by our gateways, so you can avoid needing hardware I/O devices.

- Accessories to satisfy the most difficult installations

Air purge, water cooling, and outdoor enclosures provide added security in the most demanding applications.