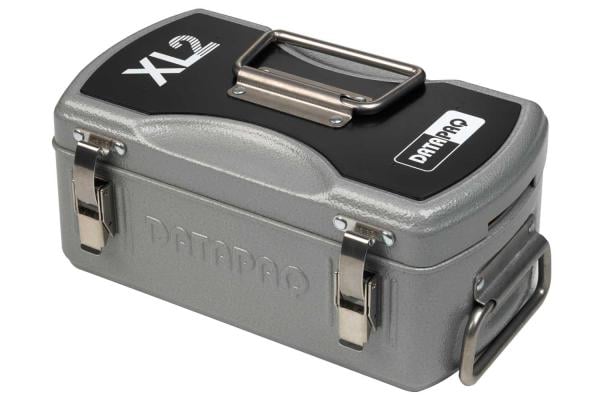

Send the Datapaq XL2 system through the oven and discover the true potential of your finishing operation quickly and efficiently.

Datapaq® Oven Tracker® XL2 Temperature Profiling System

Quick, easy and efficient oven profiling

Keep your coating cure process on target

- Use accurate profile data to optimize your oven

- Highlight oven problems immediately

- Guarantee coating/sealant/adhesive cure

- Create a clear and comprehensive profile report for your customers or regulators

The XL2 system features an intelligent data logger enabling you to record live data directly to your PC, making it an ideal choice for R&D work, IR repair oven testing and any batch cure process.

- At a Glance

- Technical Specs

- Applications

- Accessories

- Resources

XL2 Data logger

Designed with the customer in mind, the XL2 Oven Tracker System features an unique two-part data logger design. SmartPaq enables you to preprogram the MemoryPaq with your process pass/fail criteria, based on either Datapaq Value, Time at Temperature or Maximum Temperature.

The intelligent XL2 data logger will indicate if your process is out of control immediately upon exit from the oven. At the oven exit, remove from the protective thermal barrier and check the indicator on the MemoryPaq. A green LED means a successful run while red indicates a problem. Corrective action can then be taken to rectify any process problems.

The XL2 data logger features include:

- Temperature measurement range: -200°C to 1370°C (-328°F to 2498°F) (type K thermocouples)

- Simply 'plug & go', auto detection by software and auto TI configuration

- USB download from the MemoryPaq

- Sampling interval: 0.5 sec. to 50 min

- Memory capacity: 4MB

- Up to 16 measurement locations

- Onboard calibration data and service history file

Thermal barriers

The standard XL2 barrier, designed specifically for use on automotive paint lines, has a patented Silicone-free construction, eliminating concerns of contamination and possible damage to paint finishes caused by silicone products. Weighing less than 4 kg (9 lbs) ensures easy handling and transportation.

Datapaq also provides a range of thermal barriers to suit other process needs:

- High temperature protection – PTFE/Dacromet cure

- Long duration protection – aluminum aging; multiple ovens in single run (Ecoat, surfacer base etc.)

- Waterproofing – dry off ovens

- Low height clearance – two and three piece can manufacture

- 16 channel operation in single unit – automotive optimization studies

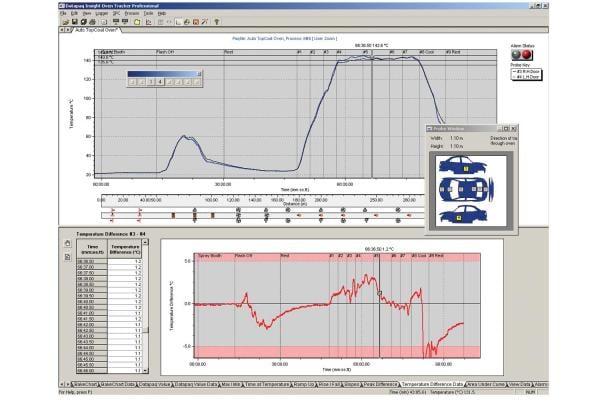

Insight software

Powerful Insight analysis software has been designed to convert raw temperature data into meaningful information that can be used to understand, control and optimize your cure process.

Choose the level of functionality to suit your needs:

Insight Basic – basic analysis package; designed for an entry-level operation.

Insight Professional – customizable full Insight analysis package; designed for top-level use within the automotive industry and features advanced analysis tools such as:

- BakeChart Analysis and Datapaq Value

- Auto update SPC (Statistical Process Control)

- Ramp up analysis tool

- Temperature Difference Probe tool

- Probe Location Product Map with linked photo library

- Advanced reporting capability

Thermocouples

Thermocouples are placed at critical points on the product to measure the temperature throughout the process. All our probes conform to the highest standards (ANSI MC 96.1 Special Limits of Error) and provide the most accurate data possible. The quad-wrapped, 10 strand 36 AWG (0.125mm), PTFE and metal braid coated probe cables are designed to withstand frequent use.

The thermocouples probes feature 'crimped' plug/cable attachment and a circular cable cross section to reduce kinking and twisting. The green cable conforms to the IEC584 color standard for Type K thermocouples.

XL2 Data logger

| Transducer Interface XL2 | TI0060 |

TI0080 |

|---|---|---|

| MemoryPaq XL2 | MP0050

|

|

| Channels | 6 |

8 |

| Dimensions | 24 x 75 x 170 mm

0.9 x 3.0 x 6.7 in |

|

| Operating temperature | -200 to 1370°C (-328 to 2498°F)

|

|

| Storage temperature | -55ºC to 100ºC (-67ºF to 212ºF)

|

|

| Memory capacity | 4MB (capable of 10 runs, 8 thermocouples, 60 mins, 5s)

|

|

| Humidity range | 0 to 85% non condensing

|

|

| Sampling interval | 0.5 sec – 50 mins

|

|

| Logger accuracy | ± 0.3 °C (0.5 °F)

|

|

| Resolution | ± 0.1°C (0.18 °F)

| |

| Thermocouple type | Type K

|

|

| Multiple run capability | Up to 10 profile runs before returning to PC

|

|

| Logger construction | Polycarbonate (max 100ºC/212ºF)

|

|

| Data collection | Plug and Go; temperature trigger

|

|

| Battery type | NiMH rechargeable

|

|

| Battery life | 50 hrs

|

|

| Fast charge | Less than 2 hours for full charge

|

|

| Additional features | SmartPaq function, onboard calibration data and service history file

|

|

TB0080 and TB081 Thermal Barriers

| Model Number | TB0080 |

TB0081 |

|---|---|---|

| Type | Stainless-steel, high-temperature thermal barrier |

Stainless-steel, long-duration thermal barrier |

| Application | High temp. coating cure applications; PTFE and Dacromet |

Aluminum aging/long low temperature cure, complete automotive paint cure line with a single uninterrupted run; E-coat, primer surfacer, base coat, clear coat. |

| Dimensions | 150 x 215 x 335 mm (5.9 x 8.5 x 13.2 in) |

182 x 236 x 370 mm (7.2 x 9.3 x 14.6 in) |

| Weight | Thermal barrier - 6.7 kg (14.8 lbs) Heatsink TB1001 - 1 kg (2.2 lbs) Heatsink TB9115B - 1.1 kg (2.3 lbs) |

Thermal barrier - 9 kg (19.8 lbs) Heatsink TB9963 - 1.5 kg (3.3 lbs) Heatsink TB1001 - 1 kg (2.2 lbs) |

| Thermal duration | 300 min @ 200ºC (392ºF) 180 min @ 300ºC (572ºF) 120 min @ 400ºC (752ºF) 100 min @ 500ºC (932ºF) 75 min @ 600ºC (1112ºF) |

24 hrs @ 100ºC (212ºF) 13 hrs @ 150ºC (302ºF) 9 hrs @ 200ºC (392ºF) 6 hrs @ 250ºC (482ºF) |

TB0090 and TB091 Thermal Barriers

| Model Number | TB0090 |

TB0091 |

|---|---|---|

| Type | Standard XL2 thermal barrier |

Low-height aluminum, silicone-free |

| Application | Automotive assembly and component supply, general paint/ powder/E-coat OEMs, large custom coaters |

2-piece can manufacture (IBO), low height, mesh belt ovens, portable system for traveling paint representatives |

| Dimensions | 134 x 187x 296 mm (5.3 x 7.4 x 11.7 in) |

104 x 187 x 296 mm (4.1 x 7.4 x 11.65 in) |

| Weight | Thermal barrier - 2.65 kg (5.85 lbs) Heatsink TB9950 - 1.0 kg (2.2 lbs) |

Thermal barrier - 2.1 kg (4.6 lbs) Heatsink TB9115B - 1.1 kg (2.4 lbs) Insert tray TB9121 - 0.2 kg (0.45 lbs) |

| Thermal duration | 11 hrs @ 100ºC (212ºF) 5 hrs @ 150ºC (302ºF) 3 hrs @ 200ºC (392ºF) 1.8 hrs @ 250ºC (482ºF) 1 hrs @ 300ºC (572ºF) |

13 min @ 200ºC (392ºF) 11 min @ 250ºC (482ºF) 10 min @ 280ºC (536ºF) |

TB5010XL and TB0083 Thermal Barriers

| Model Number | TB5010-XL |

TB0083 |

|---|---|---|

| Type | Staineless steel, IP65 waterproof |

Staineless steel, silicone-free |

| Application | Dry-off ovens or processes with water shower/rinse operations |

Automotive assembly requiring up to 16 channels |

| Dimensions | 100 x 219 x 393 mm (3.9 x 8.6 x 15.5 in) |

144 x 172 x 390 mm (5.7 x 6.8 x 15.4 in) |

| Weight | Thermal barrier - 4.5 kg (9.9 lbs) Heatsink TB9963 - 1.5 kg (3.3 lbs) |

Thermal barrier - 4.5 kg (9.9 lbs) Heatsink TB9960 - 1.45 kg (3.2 lbs) |

| Thermal duration | 10 hrs @ 100ºC (212ºF) 5.5 hrs @ 150ºC (302ºF) 3.75 hrs @ 200ºC (392ºF) 2.5 hrs @ 250ºC (482ºF) |

11 hrs @ 100ºC (212ºF) 5 hrs @ 150ºC (302ºF) 3 hrs @ 200ºC (392ºF) 1.8 hrs @ 250ºC (482ºF) 1 hrs @ 300ºC (572ºF) |

The XL2 Oven Tracker thermal profiling system is ideal for industrial coating process control, product monitoring, and quality pass/fail checks. Used across numerous industries from oven manufacturers to automotive component supply, architectural metalwork to textile coating of finished garments, the XL2 system helps with process validation, productivity increase and rapid problem solving. Several examples of where the XL2 system can be used depending on the thermal barriers include, but are not limited to, the following list below.

Click here if you would like to speak with an expert to discuss your application.

- TB0090 Standard XL2 Thermal Barrier - Automotive assembly; coating and sealant curing, automotive component supply general, paint/powder/E-coat OEM applications, large custom coaters.

- Aluminum/Silicone free TB0091 Low Height XL2 Thermal Barrier - Metal packaging, such as 2-piece can manufacture (IBO), general low height, mesh belt ovens, paint and powder suppliers; portable system for traveling paint representatives.

- TB0080 High Temperature Thermal Barrier - High temperature coating cure applications, such as PTFE and Dacromet.

- TB0081 Long Duration Thermal Barrier - Aluminum aging/long low temperature cure. Monitor complete automotive paint cure line with a single uninterrupted run (E-coat; primer surfacer; base coat; clear coat).

- TB5010-XL IP65 Waterproof Thermal Barrier - Dry-off ovens or processes where there is a risk of the system traveling via water shower/rinse operations.

- TB0083 XL2 DIB Thermal Barrier (XL2 8-16 Channels) - Automotive assembly. Monitoring new model paint lines during optimization studies that require up to 16 channels.

| Special and Custom Solutions

The experienced engineering team at Fluke Process Instruments has produced thermal barriers, heat sinks and numerous accessories for applications, ranging from temperatures of -40°C to 1350°C (-40°F to 2462°F). They can design a complete solution for your specific requirements. Contact us to request information about a custom Datapaq thermal profiling solution. |

Heatsinks for use with XL2 System

TB1001 – Stainless steel case filled with phase change material.

|

TB9115B – Heat sink used in TB0091-WH and TB0080 Thermal Barriers

|

TB9960 – Heat sink used in TB0083 Thermal Barriers

|

TB9963 – Heat sink used in TB5010-XL and TB0081 Thermal Barriers

|

Thermocouples for use with XL2 System

All Datapaq probes conform to the highest standards (ANSI MC 96.1 Special Limits of Error). The probe cables have been improved based on our 35 years of experience to make them durable and flexible. The quad-wrapped, 10 strand 36 AWG (0.125mm), PTFE and metal braid coated probe cables last significantly longer than previous designs and withstand up to 265°C (509°F). Exposed Junction Thermocouple PTFE-insulated for use in up to 2565°C (509°F), taped, spot-welded or soldered direct to components for measuring substrate temperature, can also be used to measure environmental temperatures.

Glass fiber cable 500°C (930°F) max:

|

| Adhesive Patch Thermocouple

PTFE-insulated for use in up to 2565°C (509°F) attaches directly to light gauge metal or plastic with adhesive patch and or high temperature tape. Ideal where fast response is required.

|

| Micro Mag Air Thermocouple

PTFE-insulated for use in up to 2565°C (509°F) attaches directly to ferrous substrates using a strong magnet with diameter of only 17mm (0.7in). Ideal for measuring air temperatures in the tightest of recesses.

|

| Micro Mag Surface Thermocouple

Attaches directly to ferrous substrates using a strong magnet with diameter of only 17mm (0.7in). Ideal for measuring substrate temperatures in the tightest of recesses.

|

| Magnetic Surface Thermocouple

PTFE insulated cable attaches directly to flat ferrous substrates to measure substrate temperatures.

|

| Magnetic Air Thermocouple

Attaches directly to flat ferrous substrates to measure air/environmental temperatures.

|

| Washer Thermocouple

Screwed directly to large, heavy metal substrates.

|

| Clamp Surface Thermocouple

For measuring substrate temperature.

|

| Clamp Air Thermocouple

For measuring air/environmental temperature.

|

| AluClamp Surface Thermocouple

Attaches to the edge of a panel to allow surface temperature measurement. Arm reach 300mm (12in).

|

| IRMag Surface Thermocouple

Magnetic thermocouple designed to measure ferrous substrates in IR cure ovens. Combines easy attachment with fast thermocouple response. Ideal for automotive IR repair ovens. High temperature cable rating to prevent damage from IR emitter banks. These are stainless steel braid, glass fiber insulated cable for temperatures up to 400°C (750°F).

|

| Aluminum Automotive Thermocouples

PTFE-insulated for use in up to 2565°C (509°F) and designed for surface measurement of an aluminum car body shell. The springloaded bobbin attaches to any recess in the inner car body skin. A sprung steel arm is custom adjusted to position the temperature sensor on the outer body skin.

|