Mount and Move is an innovative concept involving the integration of advanced equipment like the Fluke SV600 Acoustic Imager onto agile robotic systems, such as Boston Dynamics' Spot®. This combination enables unmanned inspections of specific locations, even in inaccessible or hazardous areas. By leveraging robotic systems, companies can augment their workforce to traverse large-scale industrial facilities day or night and perform critical tasks like data collection, asset inspections, process monitoring, and quality control checks. The Fluke SV600 and Spot are redefining industrial operations and paving the way for a new era of efficiency and safety.

Industries worldwide depend on specialized equipment for operational efficiency. However, traditionally, integrating these devices onto mobile platforms has been a complex and time-consuming process, often limiting their adaptability and hindering their effectiveness. The ‘Mount and Move’ concept disrupts this norm, allowing specialized equipment to be mounted as a payload onto robotic devices for seamless collaboration. This significantly enhances the versatility and efficiency of robotic systems, redefining industrial operations. The partnership between the Fluke SV600 Acoustic Imager and Boston Dynamics' agile mobile robot, Spot epitomizes this revolution, leading the way in infrastructure maintenance.

The Power of SV600 Certified Payload for Boston Dynamics Spot

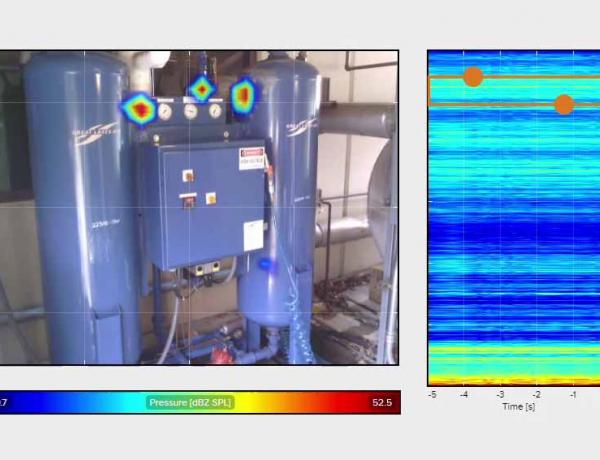

By mounting the SV600 onto Spot, the SV600 transforms into a versatile inspection platform, revolutionizing how companies tackle unique maintenance challenges. The Fluke SV600 Acoustic Imager continuously detects, locates, and visualizes air and gas leaks, as well as mechanical noise and anomalies, in real time before they become costly problems. With the release of Spot 4.1, new acoustic vibration sensing enables the detection of subtle ultrasonic anomalies, such as bearing wear, long before failure.

Spot’s renowned agility and stability allow it to navigate hazardous and hard-to-reach environments autonomously, minimizing the need for human presence in dangerous areas. Using Boston Dynamics' software application, Orbit, operators can remotely manage Spot's inspections, monitor their Spot fleet, analyze inspection data, and even teleoperate Spot.

The Benefits of Mount and Move

The combination of the SV600 Acoustic Imager payload with the Boston Dynamics Spot helps solve several challenges:

- Labor-Intensive and Time-Consuming Inspections: Manual inspections of large facilities or remote sites can be labor-intensive and prone to human error. Automating inspection tasks with Spot and the SV600 significantly enhances operational efficiency, enabling quicker data collection, streamlined inspections, and improved productivity across the board.

- Safety in Hazardous Environments: Many industries, such as oil and gas, require equipment inspections in hazardous or hard-to-reach areas. By automating repetitive and potentially dangerous tasks, Spot equipped with the SV600 reduces the need for human presence in these zones, minimizing the risk of accidents and injuries. Technicians can focus on what they do best—fixing problems—while other workers can take on more complex supervisory roles, ensuring a safer and more efficient work environment.

- Flexibility Across Applications: The combined solution of Spot and SV600 is highly adaptable, making it suitable for a wide range of industries including: oil and gas, energy, food & beverage, and utilities. Its flexibility allows users to customize it for various inspection tasks, ensuring it can meet the needs of different sectors.

- Cost Savings: While the initial investment in robotic technology like Spot and the SV600 may be significant, the long-term financial benefits are substantial. Automated inspections lead to reduced labor costs, increased equipment uptime, and improved data quality, all of which contribute to significant cost savings for businesses.

Transforming Operations

The integration of the Fluke SV600 payload with Boston Dynamics' Spot isn't just an advancement—it's a paradigm shift in industrial operations. It offers a path to increased efficiency, safety, and profitability in industries, ranging from energy, utilities, and chemical to manufacturing, aerospace, and oil & gas. Businesses that adopt this cutting-edge mount and move solution will not just keep pace with technological advancements, they will lead the charge. In an era where agility and adaptability are critical, harnessing the power of advanced robotics and acoustic imaging will keep you ahead of the curve in an ever-evolving market.

All Boston Dynamics trademarks, logos, and product names are trademarks and/or registered trademarks of Boston Dynamics, Inc. in the United States and other countries and used with permission. Other trademarks and trade names are those of their respective owners.