A global supplier of electromechanical systems implemented the SV600 Acoustic Imager to enhance their insulation testing procedures. By adopting this cutting-edge technology, the company achieved remarkable accuracy, efficiency, and employee safety improvements, setting a new standard for the industry.

Customer Overview

The customer is a renowned global supplier of electromechanical systems and services known for their commitment to renewable energy and sustainability. They have established themselves as leaders in their field, providing generators and turbines for diverse applications worldwide. With a focus on reliability and environmental responsibility, they play a pivotal role in driving the adoption of green energy solutions.

The Customer Need

The customer faced a critical challenge in their product testing and inspection processes, particularly concerning the insulation of crucial components. Their existing methods could not precisely locate potential issues, limiting their ability to ensure the highest quality and safety. Consequently, they sought a solution that would enable accurate measurement of discharges and the ability to detect specific problem areas.

Current Testing Process

The customer relied on conventional testing methods, which fell short of accurately pinpointing the location of potential issues. The existing process involved conducting tests within a controlled environment, but precise measurements required manual efforts outside the primary testing area. This approach introduced employee safety risks and led to inefficiencies in the inspection process.

The Solution: SV600 Acoustic Imager and Its Benefits

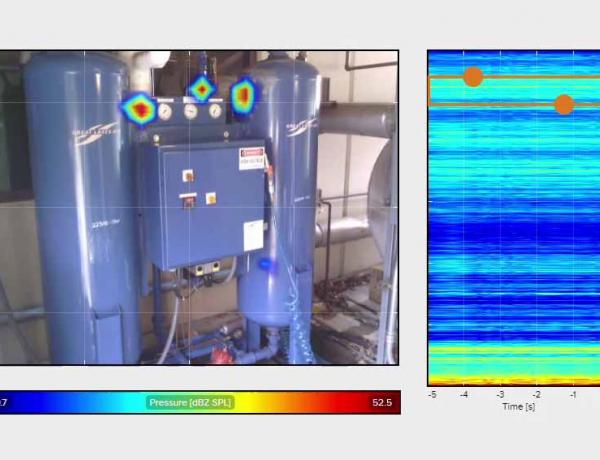

To overcome the challenges faced during the testing and inspection process, the customer integrated the SV600 Acoustic Imager into their operations. The SV600 Acoustic Imager surpassed conventional methods by providing superior visualization and precise location detection of potential issues. This improvement enabled the customer to identify specific areas requiring attention during testing, enhancing accuracy and reliability.

Continuous Monitoring and Real-time Reporting

The SV600 Acoustic Imager introduced continuous monitoring capabilities, offering real-time alarming and reporting. This ensured prompt detection of failures and facilitated immediate interventions, reducing the likelihood of unscheduled repairs and minimizing downtime.

Remote Measurement for Improved Safety

Safety concerns were effectively addressed through the SV600's non-contact remote measurement capabilities. Employees could now conduct tests from a safe distance, eliminating the need for manual measurements within potentially hazardous areas. This feature significantly improved employee safety and reduced the risk of accidents.

Automated Detection and Documentation

The SV600 Acoustic Imager facilitated the automated detection of product failures, streamlining the inspection process. It allowed for the automatic recording of images and detailed information about any identified issues, enabling deeper investigation, repair documentation, and quality reporting. This automation reduced human error and enhanced overall efficiency.

Improved Product Reliability and Reputation

By enhancing the quality assurance process, the SV600 Acoustic Imager contributed to improved product reliability. This, in turn, bolstered the customer's reputation and instilled confidence among their clients and end-users worldwide.

The successful integration of the SV600 Acoustic Imager into the customer's testing and inspection processes has significantly improved accuracy, efficiency, and safety. This cutting-edge technology, with its precise localization, continuous monitoring, and automated detection capabilities, has revolutionized the way product quality and safety are ensured.

Photo by Muhammad Nasir on Unsplash