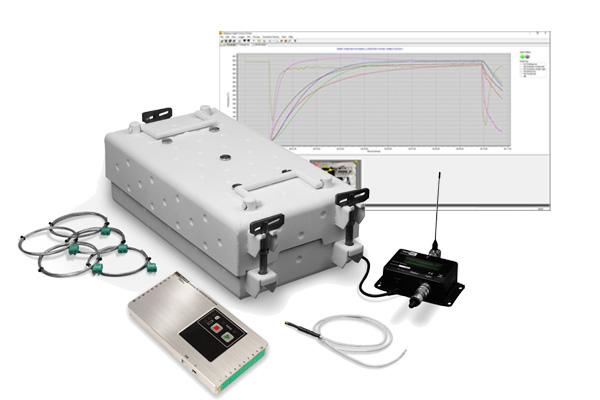

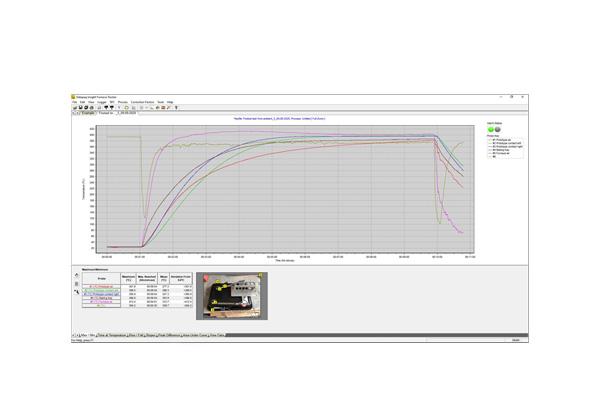

The Controlled Atmosphere Brazing (CAB) and Vacuum Furnace Tracker Systems from Fluke Process Instruments feature the Datapaq TP6 data logger, a reflective or sealed for CAB thermal barrier, thermocouples and our intuitive Insight™ Software to create a complete solution.

The CAB Furnace Tracker Systems featuring the TB4000 & TB4002 thermal barriers operate in environments up to 800°C (1472°F) and are designed for frequent use in the aggressive atmosphere present in this process.

The Vacuum Brazing Furnace Tracker Systems, which include the VB1150 & VB1151 thermal barriers, make use of reflective plate technology to eliminate the need for insulation and ensure that out-gassing from the system is minimized so production is not disrupted when profiling.

Both systems can be used to conduct temperature uniformity surveys (TUS) in compliance with CQI 29.