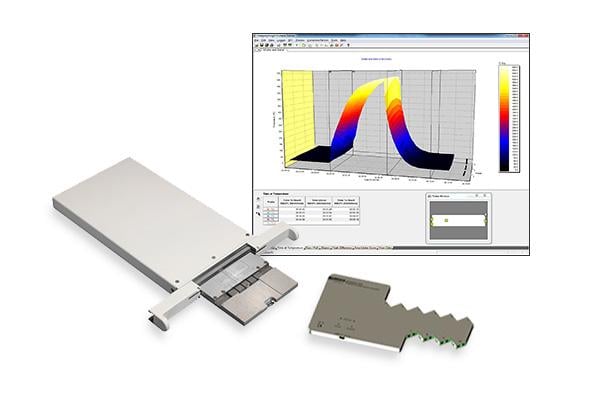

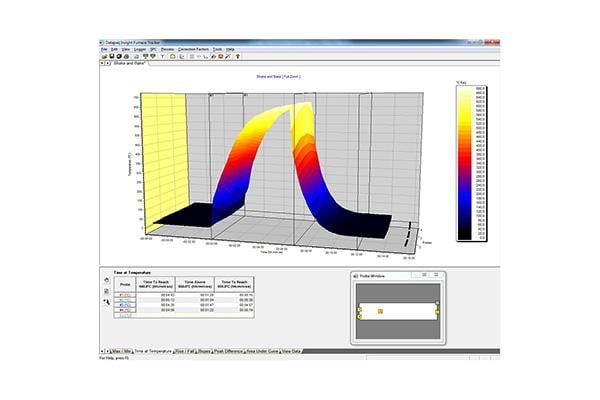

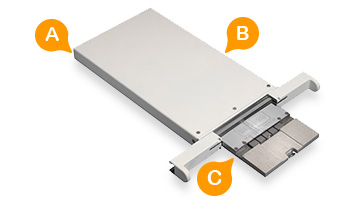

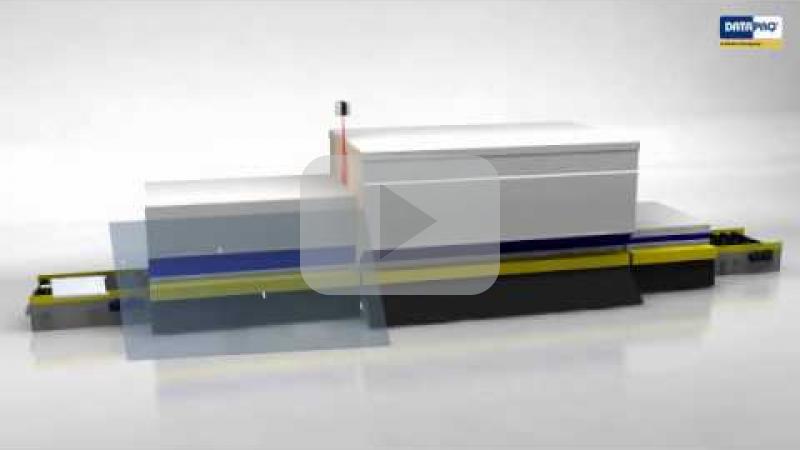

The Datapaq Furnace Tracker Systems for Glass Tempering and Bending from Fluke Process Instruments feature the Datapaq DP5 data logger, low height thermal barriers from our TB75/TB77 range, thermocouples and our intuitive Insight™ Software to create a complete solution.

This solution is optimized specifically for the glass tempering process, where the height at the furnace entrance is typically very limited. The system’s unique thermal barrier design includes an exterior ceramic coating to ensure there is no metal contact with furnace rollers. This solution ranges from 29 to 60mm (1.14 to 2.36 in.) high and can be used in temperatures up to 1000°C (1832°F).