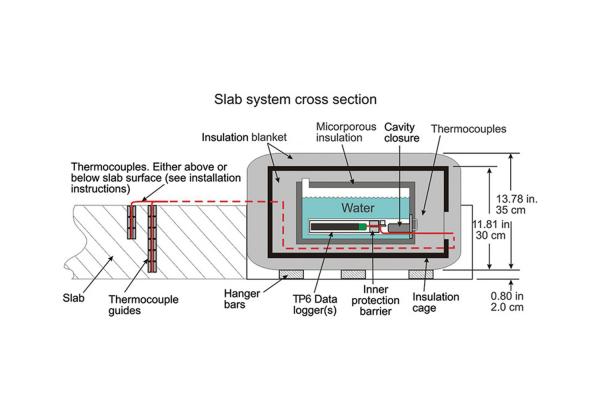

The Datapaq Furnace Tracker System from Fluke Process Instruments features the Datapaq TP6 data logger, choice of phased evaporative thermal barriers, thermocouples, and our intuitive Insight™ Software to create a complete profiling solution. Each furnace tracker can be detailed to fit into a cut out of the slab or, if height permits, they can be placed on the slab. Meanwhile, systems for billet profiling are designed to mount to the end of the billet.

Data Logger

The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ or Datapaq Insight Furnace Surveying software you can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections.

- Available in 10 and 20 channel configurations and two case styles

- Water resistant (IP67 rated)

- Communication via USB or Bluetooth

- Real time telemetry via USB, RF telemetry and Bluetooth

- Alkaline, NiMH and Lithium battery options

- Compatible with the Datapaq Insight™ for mobile application

The standard range of evaporative thermal barriers are designed for use up to a maximum operating temperature of 1250°C (2282°F). Please contact us for details of solutions for higher temperatures.

The standard range of evaporative thermal barriers are designed for use up to a maximum operating temperature of 1250°C (2282°F). Please contact us for details of solutions for higher temperatures.