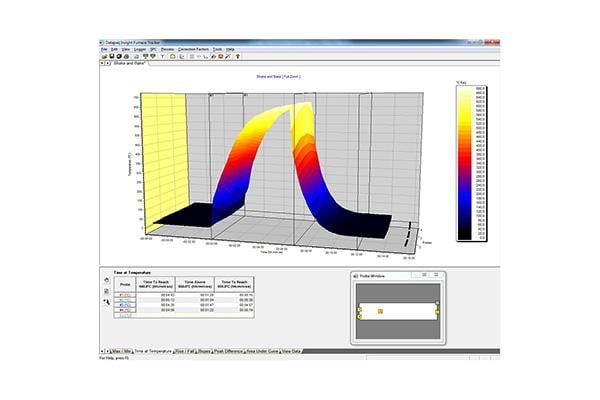

The Datapaq Furnace Tracker Specialty Profiling Systems from Fluke Process Instruments features the Datapaq TP6 and Datapaq DP5 data loggers, hundreds of application specific thermal barriers, thermocouples and our intuitive Datapaq Insight™ Software to create a complete solution.

These specialty systems enable through-process temperature profiles to be obtained in processes where long trailing thermocouples are not an option. Each thermal barrier is designed with a specific application in mind to provide the optimum solution for your process. If our current offerings of specialty systems do not meet your requirements, the engineering team at Fluke Process Instruments will design a custom thermal profiling solution. For more information, visit our customized profiling systems page.

In most applications, the environmental conditions and process parameters in the furnace – such as temperature, duration and atmosphere – drive thermal barrier selection. Although different data logger configurations and software options are available, these are less critical compared to thermal barrier selection. Some example applications are:

In most applications, the environmental conditions and process parameters in the furnace – such as temperature, duration and atmosphere – drive thermal barrier selection. Although different data logger configurations and software options are available, these are less critical compared to thermal barrier selection. Some example applications are: