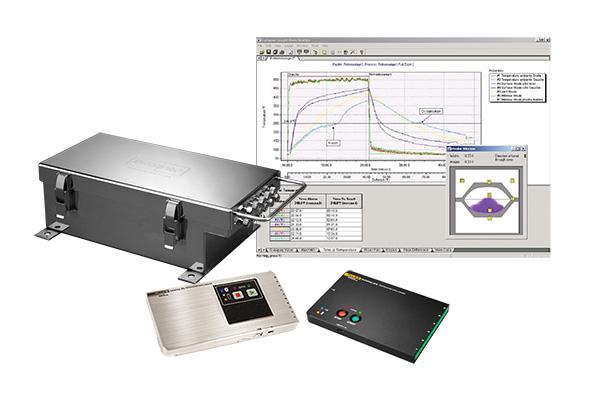

The RotoPaq system monitors temperatures of the heating and cooling cycle in the rotomolding process. The temperature data collected directly from inside the oven, mold surface or even internally within the mold, provides invaluable information about the phase transitions of the polymer on both, heating and cooling. RotoPaq Systems are offered as RotoPaq - Premium System and RotoPaq Lite - Value System.

Datapaq® RotoPaq® Thermal Profiling System

Custom solutions for Rotomolding applications

- Optimize process parameters and cycle times

- Compensate for changes in environmental conditions

- Validate new materials and processes

- At a Glance

- Technical Specs

- Applications

- Resources

Datapaq TP6 Data Logger for RotoPaq System

The Datapaq TP6, which is the heart of the RotoPaq Premium System, is a great solution for the demanding profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insight™ software, it will display information from the process in real time via the optional Radio Frequency (RF) system.

- Water resistant (IP67 rated)

- Communication via USB or Bluetooth

- Real time telemetry via USB, RF telemetry and Bluetooth

- Alkaline, NiMH and Lithium battery options

- Compatible with the Datapaq Insight™ for mobile application

Datapaq DP5 Data Logger for RotoPaq Lite System

The Datapaq DP5 data logger, combined with thermal protection and analytical software, helps you ensure your process is kept within specified tolerances. The DP5660 data logger has six channels and supports both Bluetooth and USB communication allowing you to collect product temperatures from up to six locations.

The Datapaq DP5 features include:

- Temperature measurement range: -200 to 1370°C (-328 to 2498°F)

- User replaceable Nimh battery pack

- Sampling rate as low as 0.05 seconds

- 50,000 readings per channel

- High accuracy +/- 0.5°C (0.9°F)

- Easy-to-use Start/Stop buttons

RotoPaq Thermal Barriers

Our range of thermal barriers include mounting locations to ensure easy installation. Their features include:

- Robust stainless-steel case

- Lightweight and compact design for easy installation into the mold

- Dual-phase thermal protection to allow continuous operation over multiple cycles

Oven Tracker Insight Software

Oven Tracker Insight analysis software allows comprehensive data review, analysis and reporting designed specifically for the rotomoulding application. Software features:

- Data review analysis and reporting for standard and real-time operation

- Full logger reset functionality (sample interval, start trigger)

- Auto scrolling of profile graph as data is received and plotted

- Real-time data analysis: maximum temperature, ramp rates/raw data, time at temperature and peak difference

- Alarm set-up and live data QA checks

Thermocouples

Rotopaq system includes mineral insulated thermocouples with optional guide clips to allow probe to be inserted into the mold core and secured via an external mold vent chimney. Magnetic surface probes can be used to monitor the surface temperature of a ferrous mold while patch or exposed junction probes are ideal for aluminum molds.

Datapaq TP6 Data Logger for RotoPaq System

| Model Number | TP6116 / TP6116-TM |

|---|---|

| Dimensions | 197 x 97 x 20 mm (7.8 x 3.8 x 0.8”)

|

| Channels | 10 |

| Temperature range | -100 to 1370°C (-148 to 2498°F)

Dependent on thermocouple type (Type K shown) |

| Connectivity | USB or Bluetooth*

|

| Memory capacity | 4 million data points

|

| Start/stop triggers | None (automatic), Manual, Rising/falling temperature, and time based

|

| Sampling interval | 0.2 sec – 50 mins with no telemetry

2 sec – 50 mins with RF telemetry* |

| Accuracy | ± 0.3 °C (0.5 °F) – Type K

|

| Resolution | ± 0.1°C (0.18 °F)

|

| Thermocouple type | Type K (J,N,T,R,S,B are available)

|

| Multiple run capability | Up to 10 profile runs before returning to PC

|

*Contact Fluke Process Instruments for availability of RF telemetry and Bluetooth in your country.

Datapaq DP5 Data Logger for RotoPaq Lite System

| Model Number | DP5660 |

|---|---|

| Channels | 6 |

| Temperature range | -200 to 1370°C (-328 to 2498°F) |

| Sampling interval | 0.05 sec – 10 mins |

| Accuracy | ± 0.5 °C (0.9 °F) |

| Resolution | ± 0.1°C (0.18 °F) |

| Data collection start | Start/Stop buttons, time or temperature trigger |

| Memory | 50,000 readings per channel |

| Battery | NiMH rechargeable, user replaceable |

Thermal Barriers for RotoPaq System

| Model Number | TB5000-RP |

TB5018-RP |

TB5811 |

|---|---|---|---|

| Construction | Waterproof |

||

| Dimensions | 130x220x292 mm (5.1x8.6x11.4 in) |

120x206x401 mm (4.7x8.1x15.7 in) |

100x146x303 mm (3.9x5.7x11.9 in) |

| Weight | 6.2 kg (13.7 lbs) |

8.3 kg (18.3 lbs) |

7.8 kg (17.2 lbs) |

| Suitable heatsink | 2 x TB1001 (1.0 kg / 2.2 lbs) |

||

| Barrier mount | Brackets (width 220 mm / 8.6 in) or custom |

||

| Thermal duration (in hrs) |

14.5 @ 100ºC (212ºF) 6.5 @ 150ºC (302ºF) 4.5 @ 200ºC (392ºF) 3.5 @ 250ºC (482ºF) 3 @ 300ºC (572ºF) |

17 @ 100ºC (212ºF) 8 @ 150ºC (302ºF) 5 @ 200ºC (392ºF) 4 @ 250ºC (482ºF) 3 @ 280ºC (536ºF) |

8 @ 150ºC (302ºF) 5 @ 200ºC (392ºF) 4 @ 250ºC (482ºF) 3 @ 280ºC (536ºF) |

Thermal Barrier for RotoPaq Lite System

| Model | TB5012-RP |

|---|---|

| Contruction | Stainless steel |

| Suitable logger | DP5660 |

| Dimensions | 117 x 244* x 321 mm (4.6 x 9.6* x 12.6 in) |

| Weight** | 8.4 kg (18.5 lb) |

| Thermal duration | 11.5 @ 100ºC (212ºF) 6.5 @ 150ºC (302ºF) 4.5 @ 200ºC (392ºF) 3.5 @ 250ºC (482ºF) 3 @ 300ºC (572ºF) |

* widest dimension including handle and mount brackets

** including barrier, logger and mount bracket fixing kit AS5012

Range of thermocouple options:

- Internal mold temperature monitoring: mineral insulated or glass fibre exposed junction probes

- Mold surface: magnetic surface probes for steel; taped exposed

- Oven ambient: exposed junction or magnetic / clip air probes

The Datapaq RotpPaq system is designed specifically for temperature profiling of rotomolding processes used in the manufacturing of plastic products. It allows to optimize oven set point temperatures and process parameters to maximize throughput and reduce operating costs. It also facilitates rapid and confident adoption of new designs and materials through accurate control of heating characteristics.

Complete with data logger, thermal barrier and thermocouples, the system is attached to the rotating mold assembly collecting data safely through the continuous heating and cooling cycles. With RotoPaq temperature monitoring system you can maximize the full potential of your rotomold systems and guarantee:

- Improved product quality with fewer rejects or product recalls

- Avoid warping, pinholes, bubble, surface imperfections and discoloration

- Impact resistance

- Rapid live fault-finding reducing rework, process downtime and release problems