WicketPaq system is a specialized thermal profile system designed for temperature monitoring of wicket ovens in the manufacturing of three-piece-cans.

Datapaq® WicketPaq® Thermal Profiling System

The Three-Piece-Can Profiling Solution

Custom solution for Wicket Ovens

- Find cause of under- or over-cure problems

- Confirm the wicket sheets temperature uniformity with the contour plot tool

- Identify heat migration patterns and regions of excessive turbulence

Collect the sheet and environmental temperature data and confirm print ink and lacquer cure in the wicket oven.

- At a Glance

- Technical Specs

- Applications

- Resources

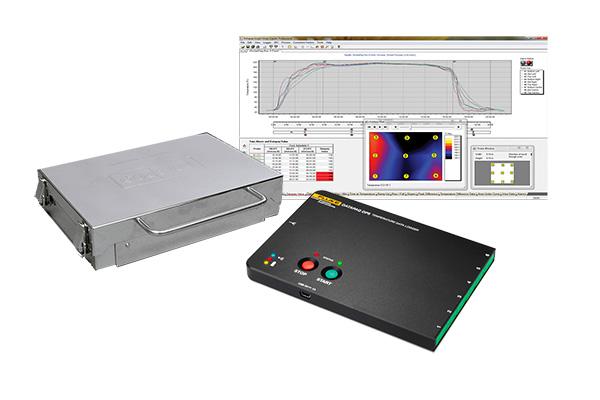

Datapaq DP5 Datalogger

Thee Datapaq WicketPaq system travels through the wicket oven measuring the surface and/or air temperatures from up to 10 thermocouples attached to the surface of the product. The data points are then stored in the memory of the data logger and analysed by the Oven Tracker Insight software.

The Datapaq DP5 features include:

- Temperature measurement range: -200 to 1370°C (-328 to 2498°F)

- User replaceable Nimh battery pack

- Sampling rate as low as 0.05 seconds

- 50,000 readings per channel

- High accuracy +/- 0.5°C (0.9°F)

- Easy-to-use Start/Stop buttons

Thermal Barriers

Designed to clip onto a sheet traveling through the oven, the whole system and test sheet can be installed quickly and easily without disturbing a production run. The shape, size and construction of the thermal barriers allows for safe runs through the wicket ovens without altering the oven operating conditions.

Oven Tracker Insight Software

The Oven Tracker Insight analysis software enables comprehensive data review, analysis and reporting. Take the guess work out of process parameter selection and reduce the need for multiple trial and error validation runs. The Datapaq Insight Software features include:

- Wicket Sheet Contour Plot

- Datapaq Value, reference and tolerance curves

- SPC (Statistical Process Control)

- Analysis Alarms

- Comprehensive Reporting, direct E-mail communication

Datapaq DP5 Data Logger

| Model Number | DP5660 |

|---|---|

| Channels | 6 |

| Temperature range | -200 to 1370°C (-328 to 2498°F) |

| Sampling interval | 0.05 sec – 10 mins |

| Accuracy | ± 0.5 °C (0.9 °F) |

| Resolution | ± 0.1°C (0.18 °F) |

| Data collection start | Start/Stop buttons, time or temperature trigger |

| Memory | 50,000 readings per channel |

| Battery | NiMH rechargeable, user replaceable |

WicketPaq Thermal Barriers

| Model Number | TB0045 |

TB0046* |

|---|---|---|

| Logger | DP5660 |

|

| Dimensions | 48x185x233 mm (1.8x7.2x9.1 in) |

70x172x240 mm (2.7x6.7x9.4 in) |

| Weight | 1.5 kg (3.3 lb) |

2.5 kg (5.5 lb) |

| Thermal duration (in min) |

80 @ 100ºC (212ºF) 45 @ 150ºC (302ºF) 35 @ 200ºC (392ºF) 30 @ 250ºC (482ºF) - |

120 @ 100ºC (212ºF) 60 @ 150ºC (302ºF) 45 @ 200ºC (392ºF) 35 @ 250ºC (482ºF) 25 @ 280ºC (536ºF) |

*Clip not provided as standard, but optional. Fitted with locking carry handle.

The Datapaq WicketPaq is a thermal profiling system design specifically for temperature monitoring of wicket ovens in the manufacturing of three-piece-cans.

To control the thermal cure processes of three-piece cans and ensure product safety and function, it is necessary to record a temperature profile through the Wicket oven. This profile demonstrates that the whole sheet surface is achieving the correct 'time at temperature' to cure either lacquer, or decorative inks and varnishes.

The lightweight and compact WicketPaq system, featuring fully programmable sample interval and start trigger, allows you to improve and optimize your can production, create documentation for process control and quality audits (ISO9000 etc.) and avoid under or over cure problems.