A Complete Solution

By monitoring temperatures at up to 10 points across the entire surface of the module, the Datapaq system provides the engineer with the information needed to set up and optimize their process. This system has been designed to eliminate the need for trailing long leads in and out of the laminator press and is therefore, significantly safer in operation than existing methods of profiling. The barrier and its surrounding frame have been designed, following consultation with equipment manufacturers, to ensure minimal stress on the laminator transport and membranes.

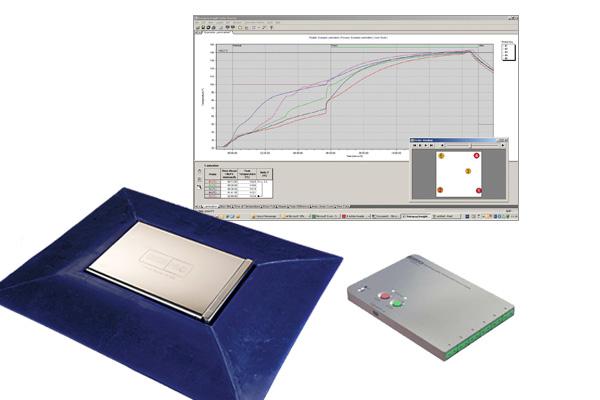

Datapaq DP5 Data Logger

The Datapaq DP5 range of loggers is intended for use in short and medium duration thermal processes; the design is optimized for low height and fast reading capabilities. The Datapaq DP5 has been designed to ensure minimum cost of use and achieves this by making use of ‘off the shelf’ charging and communication leads. In addition all of the Datapaq DP5 loggers feature a rechargeable and user replaceable NiMH battery pack, combining ease of use with lowest running costs. The user replaceable battery charges from flat to usable in just five minutes. A full charge takes only 90 minutes and can provide 20 profile runs.