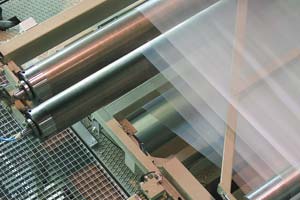

Plastic Sheet Extrusion

In plastic sheet extrusion production, polymers are melted through a slot or flat die (extruded) to form a thin, molten sheet. This sheet is is attracted towards the surface of a chilled roller where it immediately solidifies. The sheet then passes through a series of rollers which will determine thickness and texture before being edge trimmed and cut to the required size (heavy gauge sheet) or wound onto a roller (thin gauge sheet). Extruded plastic sheets are often used for thermoforming into a final shape (for example in the manufacture of refrigerator or freezer internal panels or plastic beverage cups).

- At a Glance

- Featured Solutions

Detection of die "bolt heater" problems is necessary to ensure uniformity of the die temperature, control roller temperatures and to detect film breakages.

- Linescanner facilitates control of melt curtain temperature

- Temperature measurement using spot sensor for downstream sheet temperature measurement optimizes final product quality

Other featured products

Get more information about Fluke Process Instruments solutions for this application