Offering up to 20 channels of measurement in a single system, the AutoPaq is the perfect tool for performing detailed cure validation of new installations or optimizing existing lines for new models. With real-time radio telemetry capability, this system is the preferred choice for live monitoring of automotive paint operations.

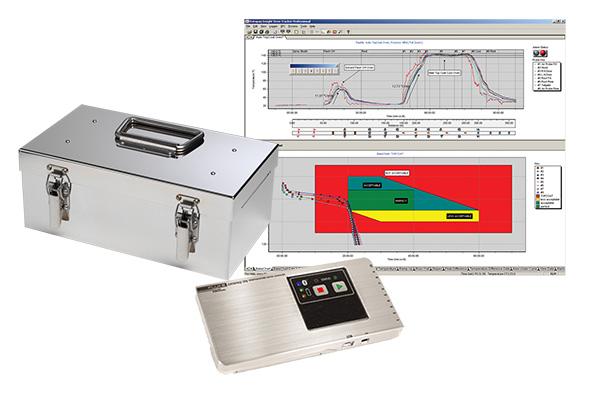

Datapaq® AutoPaq® System

The Premium Automotive Paint Profiling Solution

Measure from up to twenty points

- Validate new products and coatings accurately and efficiently

- Confirm that the process meets the cure specification

- Highlight oven problems immediately and use the accurate data to take corrective action

The Datapaq AutoPaq is a thermal profiling system designed for monitoring of paint, adhesive and sealant cure processes used in the automotive assembly market.

- At a Glance

- Technical Specs

- Applications

- Resources

Datapaq TP6 Data Logger

The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications with a 316-grade machined stainless-steel case and IP67 rating. Once combined with the Datapaq Insights software it can display information from the data logger in real time via the optional Radio Frequency (RF) system or via standard USB/Bluetooth connections.

- Available in 10 and 20 channel configurations

- Water resistant (IP67 rated)

- Communication via USB or Bluetooth

- Real time telemetry via USB, RF telemetry and Bluetooth

- Alkaline, NiMH and Lithium battery options

- Compatible with the Datapaq Insight™ for mobile application

AutoPaq Thermal Barriers

Our range of silicone-free barriers providing safe and contamination-free options to suit single and multi-run operations. Other features include:

- Robust stainless-steel case to prevent thermal damage

- Dual exit barrier with 10 or 20 channels enables easy probe placement in a car body

Oven Tracker® Insight™ Software

Oven Tracker® Insight™ analysis software enables comprehensive data review, analysis and reporting.

- Datapaq Value, reference and tolerance curves

- SPC (Statistical Process Control)

- BakeChart analysis and operator mode

- Analysis alarms

- Comprehensive reporting, direct E-mail communication

Thermocouples

Our comprehensive range of thermocouples will suit the application and product material type, whether steel, aluminum, plastic or composites.

Datapaq TP6 Data logger

|

| Model Number | TP6116 / TP6116-TM |

TP6216 / TP6216-TM |

|---|---|---|

| Dimensions | 197 x 97 x 20 mm

7.8 x 3.8 x 0.8” |

|

| Channels | 10 |

20 |

| Temperature range | -100 to 1370°C (-148 to 2498°F)

Dependent on thermocouple type (Type K shown) |

|

| Connectivity | USB or Bluetooth*

|

|

| Memory capacity | 4 million data points

|

|

| Start/stop triggers | None (automatic), Manual, Rising/falling temperature, and time based

|

|

| Sampling interval | 0.2 sec – 50 mins with no telemetry

2 sec – 50 mins with RF telemetry* |

|

| Accuracy | ± 0.3 °C (0.5 °F) – Type K

|

|

| Resolution | ± 0.1°C (0.18 °F)

|

|

| Thermocouple type | Type K (J,N,T,R,S,B are available)

|

|

| Multiple run capability | Up to 10 profile runs before returning to PC

|

|

*Contact Fluke Process Instruments for availability of RF telemetry and Bluetooth in your country.

AutoPaq Thermal Barriers TB0020 and TB0050

| Model Number | TB0020 |

TB0050* |

|---|---|---|

| Contruction | Aluminum, silicone-free |

|

| Suitable logger | TP6116 (10 channel) |

TP6216 (20 channel) |

| Dimensions | 130 x 196 x 292 mm (5.5 x 7.7 x 11.5 in) |

130 x 196 x 336 mm (5.5 x 7.7 x 13.2 in) |

| Heat sinks | Heatsink TB1001 × 2 |

|

| Thermal duration | 11 hrs @ 100ºC (212ºF) 5 hrs @ 150ºC (302ºF) 3 hrs @ 200ºC (392ºF) 1.8 hrs @ 250ºC (482ºF) 1 hrs @ 300ºC (572ºF) |

9 hrs @ 100ºC (212ºF) 4 hrs @ 150ºC (302ºF) 2.5 hrs @ 200ºC (392ºF) 1.4 hrs @ 250ºC (482ºF) 0.8 hrs @ 300ºC (572ºF) |

The Datapaq AutoPaq is designed specifically for use in automotive assembly and component supply, general paint/powder/E-coat OEMs, and large custom coaters. It allows to optimize oven set point temperatures and process parameters to maximize throughput and reduce operating costs. It also facilitates rapid and confident adoption of new designs and materials through accurate control of heating characteristics.

For more information on how thermal profiling systems are used in various coating applications, visit our Industrial Coating Applications section.