The Datapaq MonoPaq is a specialized thermal profiling system designed for temperature monitoring of the external coating cure in monoblock process used in the manufacturing of aluminum bottles. The MonoPaq2 is capable of monitoring both pin (OBO) and basket ovens (IBO) used to cure external tube and internal tube coatings. Post run, the data is transferred to the laptop or PC where the Datapaq Insight™ analysis software can review, analyze and report on the thermal profile.

Datapaq® MonoPaq® Thermal Profiling System

The Monoblock Oven Profiling Solution

Special design for specific application

- Improve quality by confirming and controlling coating cure

- Eliminate cold spots and temperature spikes

- Achieve process uniformity from line to line and batch to batch

The Datapaq MonoPaq systems are designed specifically for monitoring the coating cure process of aluminum bottles, aerosols and collapsible tubes in Monoblock ovens.

- At a Glance

- Technical Specs

- Applications

- Resources

Datapaq DP5 Data Logger

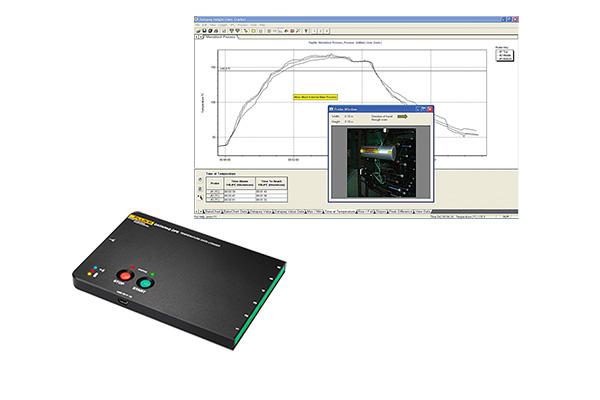

Combining DP5662 data logger with a specially designed thermal barrier and mounting bracket, the Datapaq MonoPaq system travels directly on the pin chain through the complete process. Up to 6 thermocouples can be attached to the external surface of the product (tube or bottle) and accurately measure the surface and/or air temperatures at defined intervals. The data points are then stored in the memory of the data logger.

The MonoPaq2 system combines the reduced size, 4-channel DQ1804 micro data logger with an even further reduced in size thermal barrier and mounting brackets to mount the system on OBO or IBO oven lines. This system can be used in processes with even the most demanding space limitations.

The Datapaq DP5 features include:

- Temperature measurement range: -200 to 1370°C (-328 to 2498°F)

- User replaceable Nimh battery pack

- Sampling rate as low as 0.05 seconds

- 50,000 readings per channel

- High accuracy +/- 0.5°C (0.9°F)

- Easy-to-use Start/Stop buttons

MonoPaq and MonoPaq2 Thermal Barriers

Lightweight and compact, MonoPaq thermal barriers provide excellent protection from the process environment. Mount bracket allows smooth transition of the system throughout the process, even around tight chain radii.

The MonoPaq2 thermal barrier is optimized in size to fit lines with pin spacing >45 mm (1.8in). It allows placement into wider range of products and suits interchangeable bracket/mount options of OBO or IBO ovens. This barrier permits system installation by single operator without the need to remove pin tip.

Software Insight

Oven Tracker® Insight™ analysis software allows comprehensive data review, analysis and reporting.

- Datapaq Value, reference and tolerance curves

- SPC (Statistical Process Control)

- BakeChart analysis and Operator Mode

- Analysis Alarms

- Comprehensive Reporting, direct E-mail communication

Data Loggers

| Model Number | DQ1804 |

DP5662 |

|---|---|---|

| System use | MonoPaq2 |

MonoPaq |

| Channels | 4 |

6 |

| Temperature range | -200 to 1370°C (-328 to 2498°F) |

|

| Sampling interval | 0.05 sec – 10 mins |

|

| Accuracy | ± 0.5 °C (0.9 °F) |

|

| Resolution | ± 0.1°C (0.18 °F) |

|

| Thermocouple type | Type K |

|

| Dimensions | 17×35×149mm (0.67×1.38×5.87in) |

20×57×165mm

(0.7×2.2×6.4in) |

| Battery | NiMH rechargeable, user replaceable |

|

Thermal Barrier TB0067 for MonoPaq

| Model Number | TB0067 for MonoPaq |

|---|---|

| Contruction | Stainless steel with microporous insulation |

| Suitable logger | DP5662 |

| Dimensions | 220 x 75 x 45 mm (8.6 x 2.9 x 1.7 in) |

| Weight | 1.0 kg (2.2 lb)

|

| Thermal duration | 6 min @ 200ºC (392ºF) |

Thermal Barrier Fixing Bracket (TB0061): 80 x 75 x 160 mm (3.1 x 2.9 x 6.2 in) to fit: pin diameter 5 mm (.19 in) pin spacing 95 to 125 mm (3.7 to 4.9 in) minimum radius 74 mm (2.9 in)

Thermal Barrier TB0072 for MonoPaq2

| Model Number | TB0072 for MonoPaq2 |

|---|---|

| Contruction | Stainless steel with microporous insulation |

| Suitable logger | DQ1804 |

| Dimensions | 41 x 48 x 195 mm (1.61 x 1.89 x 7.68 in) |

| Weight | 311 g (0.69 lbs) |

| Thermal duration | 11 min @ 200ºC (392ºF) 10 min @ 250ºC (482ºF) 9 min @ 300ºC (572ºF) |

Pin Line Mounting Bracket TB0073 is used with the monoblock barrier TB0072 to allow fitting directly to single product pin of a diameter 3–6mm (0.12–0.24 in) on the pin chain. Mount bracket is adjusted to suit pin diameter.

- Weight: 390 g (0.86 lbs) (barrier + mount)

- Minimum pin spacing >45mm (1.8 in)

The Datapaq MonoPaq is a thermal profiling system design specifically for temperature monitoring of the external coating cure ovens used in the manufacturing of aluminum bottles, aerosols and collapsible tubes by monoblock processes.

The MonoPaq2 is capable of monitoring both; pin (OBO) and basket ovens (IBO) used to cure external tube and internal tube coatings.

With MonoPaq and MonoPaq2 systems you can easily prove that every product goes through the specified time at temperature for satisfactory primer and decorative print cure. These systems help to eliminate temperature spikes that can cause coating damage, print discoloration and substrate damage.

In addition, MonoPaq2 is used successfully in the three-piece can coating wicket side stripe manufacturing process.