The Datapaq Oven Tracker Temperature Profiling System collects and analyses temperature information used to monitor and improve your Physical Vapor Deposition (PVD) process. The Datapaq Oven Tracker system can withstand the hostile conditions of vacuum ovens/furnaces, while maintaining a clean environment during the process.

Datapaq® Thermal Profiling System for Physical Vapor Deposition

The Temperature Profiling Solution for PVD Processes

Developed specifically for PVD monitoring

- Validate new products and coatings accurately and efficiently

- Confirm that the process meets the coating cure specification

- Highlight oven problems immediately and use data to take corrective action

- At a Glance

- Technical Specs

- Applications

- Resources

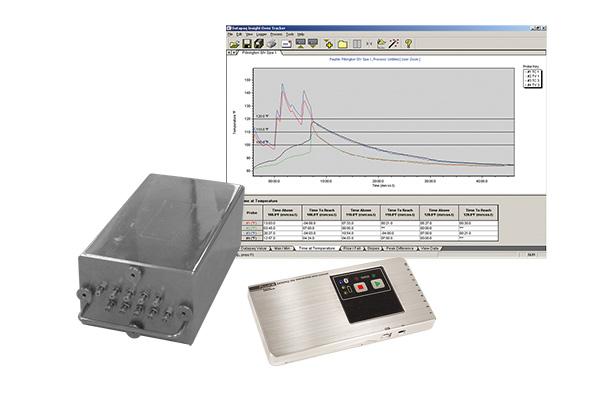

Datapaq TP6 Data Logger

The Datapaq TP6 is the perfect solution for the most demanding high-temperature profiling applications. This system mounts directly in the oven, measuring the surface from up to 10 thermocouples attached to the product.

- Water resistant (IP67 rated)

- Communication via USB or Bluetooth

- Alkaline, NiMH and Lithium battery options

- Compatible with the Datapaq Insight for mobile application

Thermal Barrier

Our range of thermal barriers provide safe and contamination-free options for your PVD process, while their robust stainless-steel case with high thermal mass prevents thermal damage in demanding environments.

Oven Tracker Insight Software

The Oven Tracker Insight analysis software allows comprehensive data review, analysis and reporting. Use the Process Optimization tool to theoretically predict the effect of profile data changes on overall profile performance using the DatapaqValue analysis. Take the guess work out of process parameter selection and need for multiple trial and error parameter validation runs with the system. The Datapaq Insight Software features include:

- Datapaq Value, Reference and Tolerance Curves

- SPC (Statistical Process Control)

- Analysis Alarms

- Comprehensive Reporting, direct E-mail communication

Datapaq TP6 Data Logger

| Model Number | Datapaq TP6 |

|---|---|

| Channels | 10 |

| Temperature range | -100 to 1370°C (-148 to 2498°F) |

| Sampling interval | 0.05 sec – 10 mins |

| Accuracy | ± 0.3 °C (0.5 °F) |

| Resolution | ± 0.1°C (0.18 °F) |

| Sample interval | 0.2 sec – 50 mins |

| Memory | 4 million datapoints |

| Battery | NiMH rechargeable, user replaceable |

TB5014 Thermal Barrier

| Model Number | TB5014 |

|---|---|

| Construction | Stainless-steel sealed face plate |

| Weight | 7.8 kg (17.2 lbs) |

| Dimensions | 100 x 146 x 303 mm (3.9 x 5.7 x 11.9 in) |

| Heat sinks | Heatsink TB1001 × 2 |

| Thermal duration | 6 hrs @ 150ºC (302ºF) 4 hrs @ 200ºC (392ºF) |

| Maximum operating temperature | 300ºC (572ºF) |

Thermocouples

- PA0710 - Mineral Insulated, Nicrobel 1.0 m (3 ft)

- PA0711- Mineral Insulated, Nicrobel 2.0 m (6 ft)

Physical Vapor Deposition (PVD) is a high-tech coating application, used to manufacture high-end consumer products, jewellery and medical products. As part of the PVD process, it is critical that the vacuum chamber temperature is carefully controlled, and that the product surface is also maintained at a specified temperature.

With Datapaq Oven Tracker system you can monitor temperatures in the vacuum chamber to guarantee correct adhesion of surface coating. This system also allows to optimize oven set point temperatures and process parameters to maximize throughput and reduce operating costs. It also facilitates rapid and confident adoption of new designs and materials through accurate control of heating characteristics.