Combining the four channel Datapaq Q18 micro data logger with a thermal enclosure and the PA1650 selective soldering sensor array, the Datapaq SelectivePaq is a complete solution for monitoring the stability of the selective soldering process.

Datapaq® SelectivePaq Thermal Profiling System

Measure the Selective Soldering Process Easily and Repeatably

Special design for specific application

- Measure process repeatability using both dip solder and preheat sensors

- Obtain real product temperatures during the selective soldering process

- Automate the selection of oven settings for faster changeover times

Designed for use in the confined space of the miniature wave selective soldering process.

- At a Glance

- Technical Specs

- Applications

- Accessories

- Resources

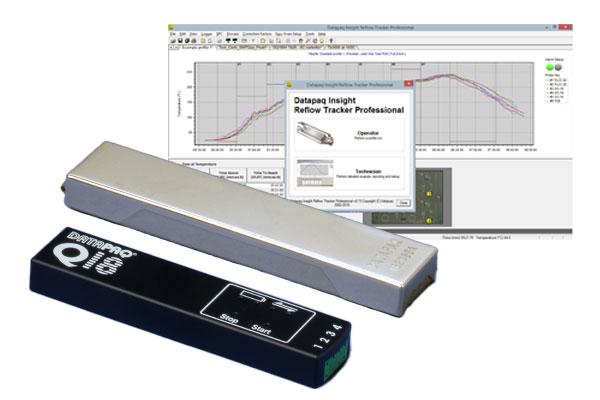

Datapaq DQ1804 Datalogger

The Datapaq DQ1804 micro data logger is housed in an aluminum case machined from a solid block providing a rugged, but lightweight enclosure. It can measure temperature at up to 20 times per second from four type K thermocouple inputs. The logger makes use of the latest micro-miniature connectors to save space and weight while maintaining ruggedness.

The Datapaq DQ1804 features include:

- Temperature measurement range: -200 to 1370°C (-328 to 2498°F)

- Small footprint - 35 mm (1.38 in) wide and 17mm (0.67in) high

- Capacity for 32,000 data-points over each channel.

- High accuracy +/- 0.5°C (0.9°F)

- Easy-to-use Start/Stop buttons

- Communication via ultra-fast USB

Thermal Barrier TB2088

The Datapaq TB2088 thermal barrier is designed to protect the data logger from the process heat and ensures maximum stability for the measuring circuits. At only 20mm (0.79in) high and 40mm (1.57in) wide it is one of the smallest system on the market.

Insight Software

The system is supplied with the full Datapaq Reflow Insight software and data analysis and includes:

- Maximum slopes

- Maximum temperatures

- Wave contact times

Datapaq Reflow Insight software is supported by wizards to guide users step-by-step through the process, ensuring accurate, consistent analysis.

Datapaq DQ1804 Datalogger

| Model Number | DQ1804 |

|---|---|

| Channels | 4 |

| Temperature range | -200 to 1370°C (-328 to 2498°F) |

| Sampling interval | 0.05 sec – 10 mins |

| Accuracy | ± 0.5 °C (0.9 °F) |

| Resolution | ± 0.1°C (0.18 °F) |

| Thermocouple type | Type K

|

| Dimensions | 17×35×149mm (0.67×1.38×5.87in)

|

| Weight | 155g (0.34lbs)

|

Thermal Barrier TB2088

| Model Number | TB2088 |

|---|---|

| Dimensions | 20×40×180 mm (0.79×1.57×7.09 in) |

| Weight | 0.3 kg (.66 lb) |

The Datapaq SelectivePaq is designed specifically for use in the confined space of the miniature wave selective soldering process. Selective soldering is replacing hand or wave soldering, as it allows greater flexibility in component layouts and produces more consistent joint quality.

To monitor this process has been a challenge on machines where the space is limited and the profiler must transit through the process measuring temperatures from the product. The Datapaq SelectivePaq addresses this size challenge while retaining the full functionality and flexibility of a reflow profiler. The optional PA1650 selective soldering sensor array can be used to measure process repeatability using both dip solder and preheat sensors.

| Special and Custom Solutions

The experienced engineering team at Fluke Process Instruments has produced numerous thermal barriers for applications, ranging from temperatures of -40°C to 1350°C (-40°F to 2462°F). They can design a complete solution for your specific requirements. Contact us to request information about a custom Datapaq thermal profiling solution. |

Thermocouples and accessories for use with the SelectivePaq System

Fast response PA1610 thermocouple fitted with micro miniature plug

|

| PA1650 – Selective soldering sensor array

The process sensor carrier plate machined from aluminum with one preheat sensor PA1651 and two dip solder sensors PA1630 provides repeatable measurements of the selective soldering machine’s performance. It is supplied complete with depth setting gauge and hex key.

|