Continuous temperature monitoring improves safety, product quality, productivity, and reliability

This article was originally posted in Plant Services, 2020.

Imagine an undiagnosed hot spot in your plant. It may signify a weakened asset surface, prior to equipment failure. It might adversely affect your food recipes or pharma processes, resulting in bad product batches. Or even worse, it might be due to improperly grounded current, something which puts the safety of your workers at immediate risk.

Thermal imaging is a mainstay of industrial monitoring and inspections for good reason. Overheating, underheating, hot spots, and other undesirable temperature-related conditions can be detected early with thermal imagers and proactively addressed before the situation escalates. Compared to the days when plants and personnel were blind to the warning signs, this is a monumental improvement.

Thermal imaging in industrial environments has conventionally been used as a periodic condition inspection function conducted with handheld infrared (IR) cameras. That use has evolved to include fixed thermal imaging to continuously or intermittently monitor critical assets, systems, processes, or safety conditions 24 hours a day 365 days a year – even remotely via a tablet or similar device. They utilize advanced cameras mounted in fixed locations and integrated with factory automation systems, and intuitive software analytics that automatically generate notifications when abnormal or inconsistent temperature events are detected.

Thanks to the capabilities of this increasingly affordable technology, imaginative temperature monitoring and control applications are extending throughout the enterprise. Today’s multipurpose solutions, such as the ThermoView TV40 thermal imaging system from Fluke Process Instruments, are simplifying crucial functions including safety inspections, product quality checks, process control, predictive maintenance, and more.

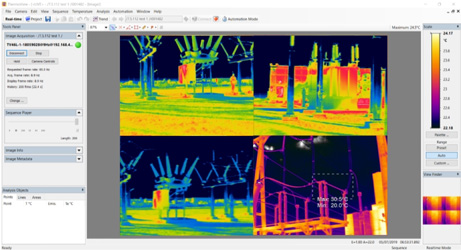

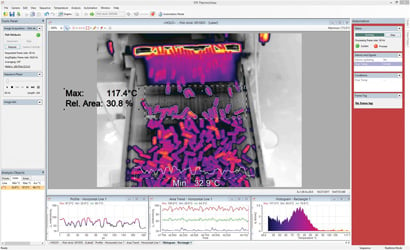

Screenshot of ThermoView Software companion to the TV40 Thermal Imager.

Thermography in Action

Fixed thermal imaging is a non-contact measurement technology designed for remote monitoring, trending, and control of temperatures. It brings unfavorable conditions or in some cases, dangerous conditions, to light so that appropriate actions can be taken proactively. Following are some successful real-world applications that hint at the technology’s vast potential for the industrial space:

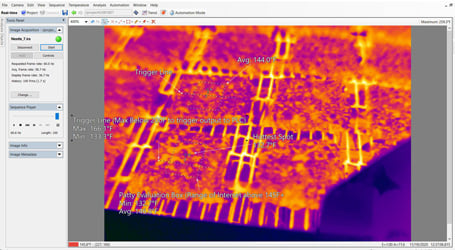

A still shot (from video) of patties moving quickly through on a conveyor after cooking in an oven.

A still shot (from video) of patties moving quickly through on a conveyor after cooking in an oven.

The trigger line (user-programmable) must be completely within the patty before the TV40 sends the output temperature to the PLC.

Personnel Safety

As a safety tool, fixed thermal imaging systems help to prevent injuries from fires, flashover, catastrophic failures, and related hazards. The cameras detect hot spots and other temperature anomalies 24/7, and automatically alert the appropriate personnel when conditions warrant so that steps can be taken to mitigate or eliminate the threat.

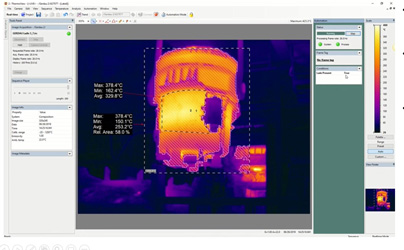

The TV40 specifically allows users to program unlimited “areas of interest” so they can continuously monitor temperature across their site. If temperatures are beyond set parameters, output accessories and auto-alarming features are activated – turning on sound alarms and light beacons or stopping equipment before it can harm operators in the area. For example, vessels that hold molten material pose a potentially significant safety risk to workers in the vicinity. One copper smelting plant has a fixed thermal imaging system continuously monitoring the outer steel surface of its kilns to detect hot spots, which indicate the refractory is breaking down. In a steel plant, a thermal imager is positioned to monitor steel ladle surfaces for inconsistent temperatures and hot spots, and operators are notified when pre-set parameters are exceeded. In both cases, the early detection of thermal inconsistencies with a fixed thermal camera can avoid the cost of lost batches and reduce the ROI payback period of the camera purchase. A chemical processing facility using thermal imaging to monitor the exterior of their vessel as part

of their critical asset monitoring program.

A chemical processing facility using thermal imaging to monitor the exterior of their vessel as part

of their critical asset monitoring program.

- Consider the safe operation of ovens used in food, pharmaceutical, and chemical processing plants. A fixed imager is pointed at an enclosed chemical oven used in rubber-based product manufacturing to confirm the product’s temperature prior to opening the oven, helping to ensure operator safety and avoid fires.

- Fixed imaging systems also are used to remotely monitor assets, such as at utility substations, eliminating hazardous in-person inspections and allowing maintenance to be carefully planned with suitable protective measures.

- Additionally, remotely monitoring critical assets can save companies the cost associated with in-person inspections across multiple locations, especially in industries like clean energy where locations might be spread across miles.

- They are also beneficial for environmental monitoring, such as detecting hot spots in coal or biomass stockpiles to avoid spontaneous combustion and major fires.

Product Quality

Consider what a typical manufacturing floor is producing, what is the return on investment of catching just one batch of bad of product before it goes out the door to the hands of their customer? Thermal imaging systems are useful for increasing the quality, verifying product specifications, and providing traceability of temperature- sensitive products and minimizing rework rates. Infrared and visual feeds paired with autoalerts to temperature changes and out-of-spec conditions allow production teams to quickly make necessary adjustments. For instance, a food manufacturer deployed integrated continuous monitoring with fixed thermal imaging at its cooking ovens so that operators can validate the food is cooked to the proper temperature prior to packaging. An automotive glass manufacturer is getting immediate pass/fail results on whether the electrical strips in its heated backlight window defroster grids perform to required specifications, saving time on traditionally long testing procedures and increasing throughput. A chemical application involves detecting hot spots on ceramic-lined products during production to ensure the end product’s overall quality is not diminished by excessive heat. If a user is running a continuous process, they can program the TV40 to take an image and record the data every time a product fails. During an 8-hour shift, the user can review any products that failed to meet the programmed specifications and further investigate not only what products failed specification but also why.

Precooked food is being monitored for process control to ensure fish sticks (pictured here) are not overcooked.

Precooked food is being monitored for process control to ensure fish sticks (pictured here) are not overcooked.

Plant Productivity

Fixed thermal imaging also improves process control and throughput by implementing continuous infrared and visible sighting to detect inconsistent or excessively high temperatures. This allows operators to efficiently take correct actions or allow the system to take control of the process with user-determined commands.

For example, a manufacturer of vinyl flooring is using the technology to monitor production temperature consistency, which is critical to ensuring multilayer bonding of the material. A high-carbon steel processing plant is using fixed thermal imaging to monitor the product’s temperature as it goes through the customization process to ensure it is evenly heated. In both cases, the process control system put in place with fixed thermal imaging and user-determined commands enables reduced costs on rework, increased throughput, and improved uptime.

Equipment Reliability

Increasing asset uptime is also important to service reliability and customer satisfaction. A handheld camera is only as good as how often the data is being collected. Without the 24/7 focus of a fixed or PTZ thermal imaging system, hot spots on critical assets can be missed, leading to at best a bad batch and at worst a catastrophic asset failure and unplanned downtime. For example, an electric power utility can use a thermal imaging system for continuous monitoring and predictive maintenance of its remote transformer bushings and generator brush assemblies, helping to improve system reliability and efficiency. The added load on bushings can generate heat unpredictably, and without an imager fixed in place to catch each of those spikes in heat, it would be impossible to address those temperature fluctuations and keep the assets operational.

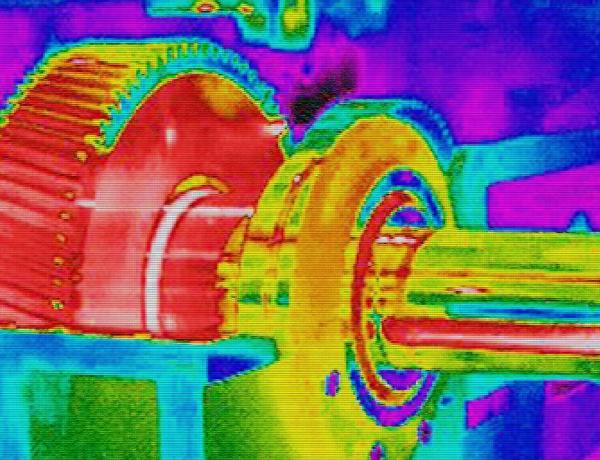

Monitoring a critical asset with high temperatures, ensuring there are no hot spots within the ladle.

Monitoring a critical asset with high temperatures, ensuring there are no hot spots within the ladle.

Advanced Thermal Imaging Capabilities

Each of the above applications and others like them are possible with the ThermoView TV40 thermal imaging system(s). The TV40 system accommodates several technology options, including fixed or PTZ cameras as well as single or multi-camera deployments, and the option to integrate remote access to camera data on your networked systems and devices (i.e., phone, laptop, tablet). The multi-purpose camera and software package was designed specifically for critical industrial monitoring applications. The imager captures, displays, and archives both visible and infrared images, and can be customized to monitor set areas of interest continuously, intermittently, or independently. It produces actionable analytics and generates user-programmed alarms when parameters are outside of established high and low temperature setpoints – whether by email, Modbus, EtherNet/IP, or digital outputs. Images can be taken and emailed to technicians at the point when the alarm is generated. The TV40 imager, designed for use in the most challenging environmental conditions, has multiple mounting options and can operate standalone or networked into a control system. Large processes or areas can be monitored with multiple fixed cameras or a single Pan and Tilt camera. The Pan and Tilt accessory housing, rated IP66 for harsh environments, supports continuous 360º rotation as well as -40º upward and 90º downward motion. Additional accessories such as the high temperature enclosure, outdoor enclosure, air-purge system combined with expandable digital and analog I/O options provide different layers of protection and control. The system’s ThermoView software helps users understand temperature trends, differential temperatures, and absolute temperatures in real time. They can view continuous thermal and live visual feeds simultaneously, side by side, along with analytics designed to keep processes, products, and sites under control around the clock. From monitoring food ovens and transformer operations to analyzing product batch quality and improving electrical safety, a fixed thermal imaging system like the ThermoView TV40 helps you improve your process operations while enhancing worker safety.

For more information, see the following articles: