The EasyTrack3 Thermal Profiling System is designed for temperature profiling of powder coating ovens and products and provides an easy, robust, powerful oven profiling tool.

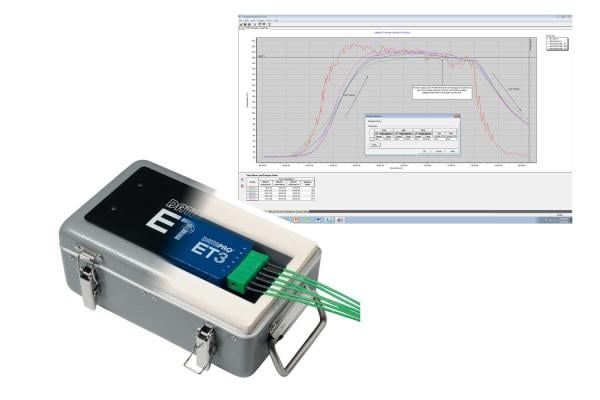

Datapaq EasyTrack3 Thermal Profiling System

Profile Your Oven the Easy Way

Easy, efficient, economic

- Easily measure air and product temperatures through your curing process

- Optimize your coating oven performance and save energy costs

- Identify potential problems in your coating process and correct them quickly and efficiently

Send the EasyTrack3 system through your oven and measure the product and oven temperature to guarantee that the correct time at temperature is achieved.

- At a Glance

- Technical Specs

- Applications

- Accessories

- Resources

Datapaq ET3 Data Logger

The ET3 datalogger guarantees accurate temperature profiling and is designed with easy two-button operation. The plastic cool-touch case allows safe and comfortable handling even after the most demanding runs. Supplied with onboard calibration certificate, the ET3 temperature logger provides complete traceability.

The ET3 data logger features include:

- Temperature measurement range: -150 to 500°C (-238 to 932°F)

- Choice of 4 or 6 channels

- Simply 'plug & go' with auto-detection by software

- SmartPaq for simple runs “pass” or “fail” indication at oven exit direct from logger

- Sampling rate as low as 0.5 second

- Memory capacity: 18.000 readings per channel per run

- Multiple run capability of 3 runs separately stored in logger

- Onboard calibration data

Thermal barriers

The EasyTrack3 profiling system comes with a range of thermal thermal barriers that guarantee robust thermal protection and continuous performance run after run.

- The TB0253 thermal barrier provides 2 hours protection at 200°C (392°F); with weight of only 3kg (6.5 lbs) and height of 110mm (4.3 in), it’s easy to transport.

- The TB0263 thermal barrier is designed for more demanding powder coating processes where multiple runs back to back are necessary and provides protection for 3hrs at 200C (392F).

The EasyTrack3 system can be offered with other thermal barrier options for high temperature cure processes (PTFE, Dacromet, etc) or space limited applications.

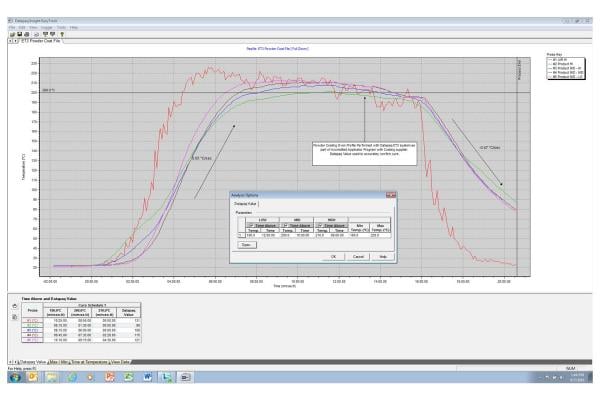

EasyTrack Insight™ Software

The EasyTrack3 temperature profiling system comes with two choices of software; standard EasyTrack Insight or EasyTrack Insight Professional.

Both software versions confirm that cure temperatures meet paint manufacturers’ specifications, make comparisons probe-to-probe, identify that the Datapaq values fall within an acceptable tolerance range and evaluate process parameter changes. With a simple click of the mouse, you can print out a profile report that will satisfy all necessary regulatory requirements.

In addition, the Professional software package unlocks advanced features of the ET3 datalogger, such as multiple run and SmartPaq operation. It also provides an enhanced analysis and reporting platform allowing.

ET3 Data Logger Specifications

| Model | ET4043 |

ET6063 |

|---|---|---|

| Case | High temperature molded polycarbonate

|

|

| Channels | 4 |

6 |

| Weight | 196 g (0.43 lbs) |

200 g (0.44 lbs) |

| Dimensions | 170 × 67 × 20.5 mm (6.7 × 2.6 × 0.8 in)

|

|

| Measurement temperature range | -150 to 500 °C (-238 to 932 °F)

|

|

| Logger operating range | 0 to 85 °C (32 to 185 °F ) with auto shut-down |

|

| Memory capacity | 18.000 readings per channel per run

Non-volatile hot data protection. |

|

| Sampling interval | 0.5 sec – 60 mins

|

|

| Logger accuracy | ± 0.5 °C (0.9 °F)

|

|

| Resolution | ± 0.1°C (0.18 °F)

|

|

| Thermocouple type | Type K (mini-plug)

|

|

| Multiple run capability | Max 3 runs separately stored in logger

|

|

| Start trigger | Auto start / start button / temperature trigger

|

|

| Battery type | Replaceable 9V alkaline

|

|

| Battery life | 50 × 1 hour oven runs – 5 s, 6 channels at 70 °C (158 °F)

|

|

| Additional features | SmartPaq function*, intelligent power management, auto detection by Insight software, CJC (Cold Junction Compensation), hot data protection, non-volatile memory, real-time data, onboard calibration

|

|

* Requires Insight Professional software

Standard EasyTrack3 Thermal Barriers

| Model Number | TB0253 |

TB0263 |

|---|---|---|

| Construction | Aluminum |

|

| Dimensions | 265 × 185 × 110 mm (10.4 × 7.3 × 4.3 in) |

297 × 187 × 125 mm (11.7 × 7.4 × 4.9 in) |

| Weight incl. barrier and heat sink | 3 kg (6.5 lbs) |

3.7 kg (8.2 lbs) |

| Thermal duration* @100°C (212°F) @150°C (300°F) @200°C (400°F) @250°C (480°F) @300°C (570°F) @400°C (750°F) |

(in min.) 330 180 120 75 40 - |

(in min.) 540 270 180 110 60 - |

| Heatsink | TB9550 - Phase change temperature 58°C (135°F) |

|

Low-height and high-temp EasyTrack3 Thermal Barriers

| Model Number | TB2037 |

TB5000-HT |

|---|---|---|

| Construction | Stainless steel |

|

| Dimensions | 229 × 90 × 31 mm (9.0 × 3.5 × 1.2 in) |

292 × 190 × 130 mm (11.5 × 7.5 × 5.1 in) |

| Weight incl. barrier and heat sink | 0.55 kg (1.2 lbs) |

6.2 kg (13.7 lbs) |

| Thermal duration* @100°C (212°F) @150°C (300°F) @200°C (400°F) @250°C (480°F) @300°C (570°F) @400°C (750°F) |

(in min.) 30 18 13 9 - - |

(in min.) 870 390 270 210 180 90 |

| Heatsink | NA |

TB1001x2 Phase change temperature 58°C (135°F) |

*Values assume constant environmental temperature

The EasyTrack3 thermal profiling system is ideal for industrial coating process control, product monitoring, and quality pass/fail checks.

Several examples of where the EasyTrack3 system can be used depending on the thermal barriers include, but are not limited to, the following list below. Click here if you would like to speak with an expert to discuss your application.

Thermocouples for use with EasyTrack3 System

All Datapaq probes conform to the highest standards (ANSI MC 96.1 Special Limits of Error). The probe cables have been improved based on our 35 years of experience to make them durable and flexible. The quad-wrapped, 10 strand 36 AWG (0.125mm), PTFE and metal braid coated probe cables last significantly longer than previous designs and withstand up to 265°C (509°F). Exposed Junction Thermocouple PTFE-insulated for use in up to 2565°C (509°F), taped, spot-welded or soldered direct to components for measuring substrate temperature, can also be used to measure environmental temperatures.

Glass fiber cable 500°C (930°F) max:

|

| Adhesive Patch Thermocouple

PTFE-insulated for use in up to 2565°C (509°F) attaches directly to light gauge metal or plastic with adhesive patch and or high temperature tape. Ideal where fast response is required.

|

| Micro Mag Air Thermocouple

PTFE-insulated for use in up to 2565°C (509°F) attaches directly to ferrous substrates using a strong magnet with diameter of only 17mm (0.7in). Ideal for measuring air temperatures in the tightest of recesses.

|

| Micro Mag Surface Thermocouple

Attaches directly to ferrous substrates using a strong magnet with diameter of only 17mm (0.7in). Ideal for measuring substrate temperatures in the tightest of recesses.

|

| Magnetic Surface Thermocouple

PTFE insulated cable attaches directly to flat ferrous substrates to measure substrate temperatures.

|

| Magnetic Air Thermocouple

Attaches directly to flat ferrous substrates to measure air/environmental temperatures.

|

| Washer Thermocouple

Screwed directly to large, heavy metal substrates.

|

| Clamp Surface Thermocouple

For measuring substrate temperature.

|

| Clamp Air Thermocouple

For measuring air/environmental temperature.

|

| AluClamp Surface Thermocouple

Attaches to the edge of a panel to allow surface temperature measurement. Arm reach 300mm (12in).

|

| IRMag Surface Thermocouple

Magnetic thermocouple designed to measure ferrous substrates in IR cure ovens. Combines easy attachment with fast thermocouple response. Ideal for automotive IR repair ovens. High temperature cable rating to prevent damage from IR emitter banks. These are stainless steel braid, glass fiber insulated cable for temperatures up to 400°C (750°F).

|

| Aluminum Automotive Thermocouples

PTFE-insulated for use in up to 2565°C (509°F) and designed for surface measurement of an aluminum car body shell. The springloaded bobbin attaches to any recess in the inner car body skin. A sprung steel arm is custom adjusted to position the temperature sensor on the outer body skin.

|