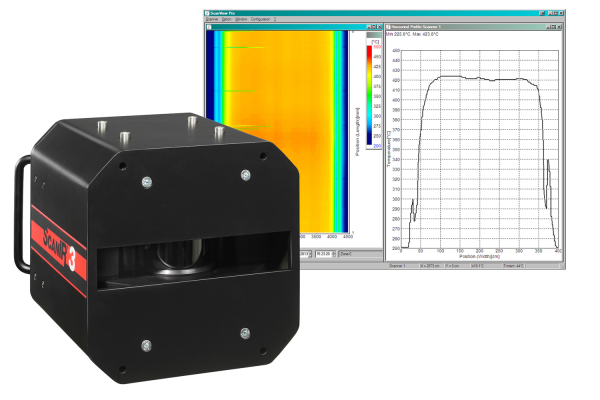

The ScanIR3 thermal scanner is designed for a wide variety of noncontact temperature measurement applications, including those in harsh industrial environments. Its robust housing incorporates standard water-cooling and air purge and features built-in laser sighting. A rugged processor box provides universal input and output (I/O) capabilities in the field without the need for an external computer.

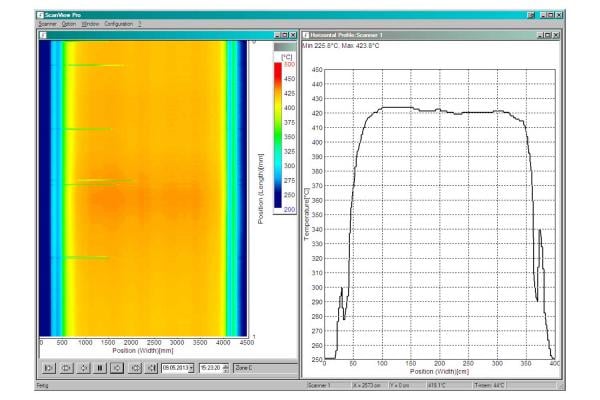

The ScanIR3 linescanner and thermal imaging system has one of the fastest scan speeds in the industry and offers complete data about even the highest-speed manufacturing processes. Unlike point sensors that measure a single point, the linescanner measures multiple temperature points across a scan line. Its motorized mirror scans at rates up to 150 lines per second, allowing rapid detection of temperature non-uniformities and hot spots. Rotating optics collect infrared radiation at 1024 points within a 90-degree field of view, and industry-leading optical resolution (up to 200:1) enables detection of smaller temperature anomalies.

The ScanIR3 system is exceptionally easy to deploy and manage: a single bundled sensing head cable with a one-click connector to the scanner allows for fast and trouble-free installation. The unit’s processor box supports various industry interfaces, including Ethernet, fiber optics (optional), and analog/digital I/O.

Key Features:

- Thermal scanner temperature range: 20 to 1200°C (68 to 2192°F)

- Operating ambient temperatures without cooling: 5 to 50ºC (32 to 122ºF) and with integral water-cooling: 180ºC (356ºF) maximum

- Operating ambient temperatures with optional internal heater: -40ºC (-40ºF) minimum

- Fast scan speed up to 150 lines per second

- High optical resolution up to 200:1

- PC independent input/output capabilities

- Reliable Ethernet Communication

- Rugged, waterproof housing with built-in laser

- Built-in air purge and water cooling as standard

- Field-replaceable window

- One bundled sensing head cable with one-click connector to the scanner